Overview

Impressively spacious, TT52 PRO offers a unique and exhilarating flying experience for both amateur and professional flyers. The enlarged flight chamber allows to practice all modern indoor skydiving competition disciplines including 8-way formation and dynamic disciplines. TT52 PRO is the perfect venue to host world championships and other high-level indoor skydiving competitions. Its exceptional performance, safety, and energy efficiency make it an attractive choice for event organizers and competitors alike. Best suitable for highly populated areas with competing 14ft indoor skydiving projects.

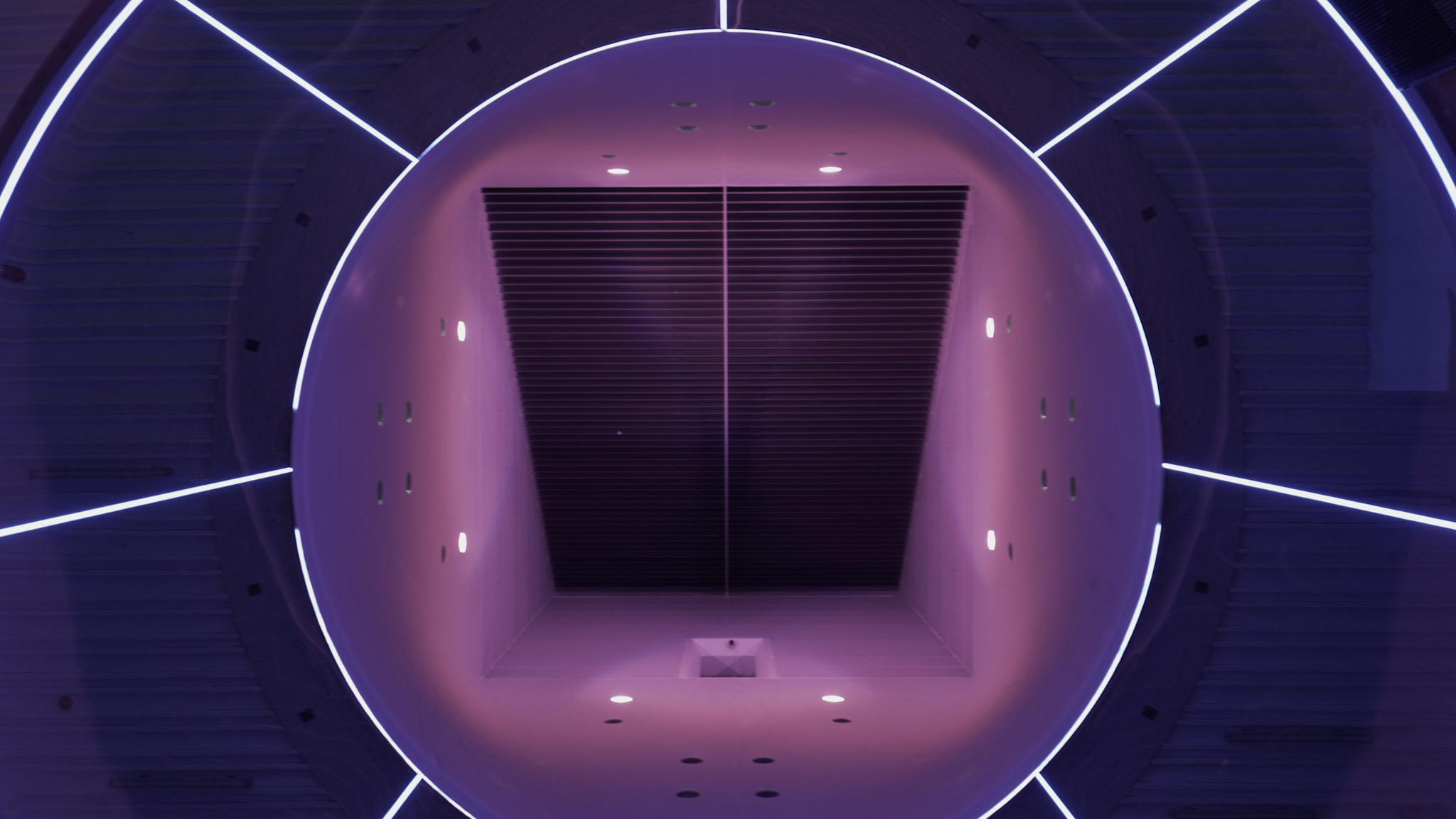

The large 5.2-meter-diameter flight chamber provides an overwhelming area to experience indoor skydiving at its best. The multi-level glass section comprises of a 4-meter-tall cylindrical bottom part and a 4-meter-tall conical upper part. The frameless design allows the best views for both flyers and spectators. Transparent and exceptionally durable chemically strengthened glass guarantees maximum safety even during training sessions with metal gear.

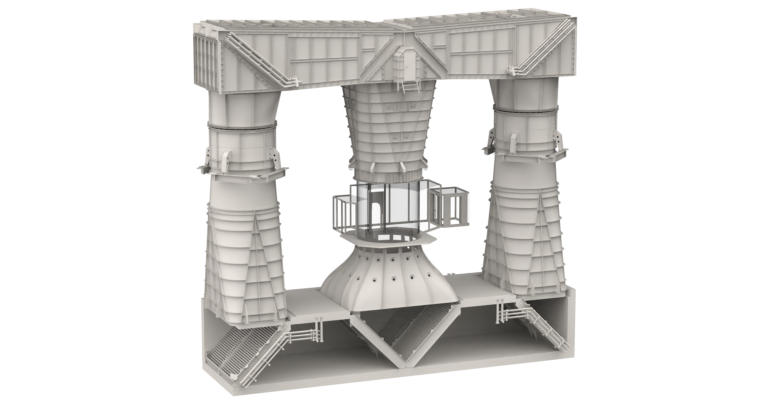

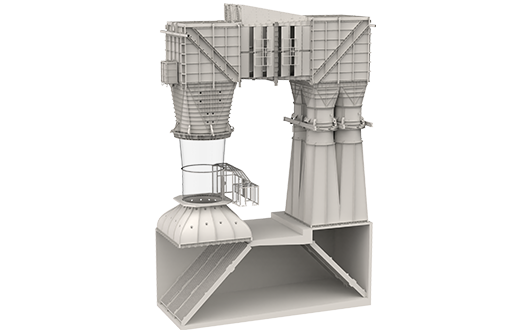

TT52 PRO is an extremely powerful machine suitable for sport training in groups up to 8 persons and military training with full gear. Operational costs are a significant factor in the success of any indoor skydiving project, especially when it comes to big-sized wind tunnels. TT52 PRO’s enhanced aerodynamic design includes 4 extra-large low RMP axial fans with carbon fibre blades located in the vertical air duct. This design benefits the energy efficiency, ensuring lower running costs and a greener approach to indoor skydiving.

Putting safety at the forefront, TT52 PRO features 1.9 flight chamber diffusion ratio, innovative safety net with near-the-wall deflection, and a curved collision safe entrance to the flight chamber. Highly praised by pro flyers, these features create the most secure environment for those who have no experience in indoor skydiving.

World Championship Suitability

The TT52 is the perfect venue to host world championships and other high-level indoor skydiving competitions. Its large flight chamber and industry-leading height enable dynamic disciplines and provide an unparalleled flying experience for athletes. The exceptional performance, safety, and energy efficiency features of the TT52 make it an attractive choice for event organizers and competitors alike.

With its cutting-edge technology and design, the TT52 is a top choice for any indoor skydiving project. From shopping malls to dedicated skydiving centers, the TT52 offers a world-class experience that attracts enthusiasts and casual flyers alike. With its visually striking appearance and exceptional flying capabilities, this wind tunnel is a fantastic investment for businesses looking to create unforgettable experiences for their customers.

To provide a comfortable flying experience in any climate zone, TT52 PRO comes equipped with both an outright ventilation system and an optional active cooling system. In regions where low temperatures are predominant, the ventilation system can further enhance energy efficiency, leading to additional savings of up to 35%. Cooling the airflow is essential for hot climate zones. The active cooling system involves hollow turning vanes that effectively cool the air while keeping the airflow quality at the top.

Specification

| Flight сhamber inner diameter | 5.2 m (17″) |

| Glass height default | 8 m (26’2″) |

| Glass height maximum | 20 m (65’6″) |

Dimensions Double Loop

| Flight сhamber inner diameter | 5.2 m (17″) |

| Glass height default | 8 m (26’2″) |

| Glass height maximum | 20 m (65’6″) |

Dimensions Single Loop

| Height | 38.5 m (126’3″) |

| Length | 28.5 m (93’5″) |

| Width | 11.2 m (36’7″) |

| Power capacity (min) | 1800 kW |

| Average time-weighted power consumption | 680 kW |

| Power consumption @ 180 km/h | 500 kW |

| Standard power capacity | 1800 kW |

| Advanced power capacity | 2000 kW |

| Beast power capacity | 2240 kW |

| Noise level | 60 dBa (optional) |

| Darcy-Weissbach drag coefficient, Xi | 0.245 |

| Max. Speed @ Standard power capacity | 275 km/h |

| Max. Speed @ Advanced power capacity | 286 km/h |

| Max. Speed @ Beast power capacity | 296 km/h |

| Diameter | 5.2 m (17′) |

| Height (minimum) | 21.2 m (69’6″) |

| Area | 21.22 m (69’6″) |

| Default glass height | 8 m (26’2″) |

| Glass type | chemically strengthened, non-shattering |

| Glass total thickness | ≥50 mm |

| Low iron glass | yes |

| Optional maximum glass height | up to 20 m (65’6″) |

| BASE jumping chamber height | 18 m (59′) |

| Patented safety net | maintains long stroke in close proximity to the walls |

| Safety net tensioner | 2 per cable |

| Speed drop (Diffusion rate) | 1.9 |

| Portal entrance shape | curved, collision safe |

| Portal entrance material | impact-dampening rubber |

| Entrance area speed drop | ≤1% |

| Airlock doors | automated |

| Airlock emergency exit | yes |

| Smooth decompression | yes |

| Supplier | Tunneltech , Germany |

| Quantity | 4 |

| Power (per fan) @ Standard power capaccity | 450 kW |

| Power (per fan) @ Advanced power capacity | 500 kW |

| Power (per fan) @ Beast power capacity | 560 kW |

| Location | return vertical airduct |

| Axel orientation | vertical |

| Diameter | 3.37 m (11′) |

| Effective crossectional area | 7.68 sq.m. |

| Blades material | carbon fibre |

| Blades count | 8 |

| Automated lubrication | yes |

| Material of FC Airjet (FC Contraction) | FRP |

| Material of FC Diffuser | glass |

| Material of return vertical airducts | FRP/steel |

| Ventilation (a.k.a. Passive Cooling) | yes |

| Max ventilation to airflow ratio | 22% |

| Active Cooling System | yes (optional) |

| Additional drag, caused by active cooling system | 0 Pa (No drag) |

| Active Cooling type | through turning vanes |

| Recommended Chiller Cooling Capacity | 1200 kW (4,094,570 BTU/h) |

| Color LED backlight strips between glass panels | yes, flicker-free (optional) |

| LED Strips power per m | 10 W |

| LED Strips frame rate | 60 fps |

| LED Projectors | yes, flicker-free (optional) |

| LED projectors default number installed (optional) | 8 – 32 (optional) |

| LED projectors max. power | 90 W |

| LED projectors max. luminous flux power | R:1950 G:2700 B:750 lumen |

| LED projector dimming capability | 0 – 100% |

| LED control from Main Panel | yes |

| LED anti-flicker function | high frequency PWM |

| LED projector PWM frequency | 1 kHz |

| LED color depth | 24 bit, 16,777,216 colors |

| LED projector color depth | 36 bit, 64 bln colors |

| Main panel control display | 28″ |

| Touch screen main panel | yes |

| Flight chamber info display | 31.5″ |

| Operator desk speed controller | autonomous knob |

| Waiting zone speed controller | autonomous knob |

| Base chamber speed controller | autonomous knob |

| Speed controller knob resolution | 0.1% |

| Chord | 500 mm |

| Chord-to-Spacing ratio | ≥3:1 |

| Material | aluminium |

| Surface treatment | anodized |

| Cooling channels | 6 |

| Turning vane heat transfer ratio, per meter @ 10-35m/s airflow speed | >105 (±15) W/(m*K) |

TT52Pro Double loop (PF52DL)

PF52DL Building Requirements (brief) – n/a

PF52DL Technical Documentation can be developed on request.

Please see PF52SL model documentation.

TT52Pro Single loop (PF52SL)

PF52SL Technical Documents (full version). The full technical documentation is available upon request. Please contact us.

Document archive contents:

- Building Requirements (A)

- Wind tunnel equipment location (T)

- Equipment loads (E)

- Equipment bases tolerance requirements (H)

- Cooling System (C)

- Cable networks (P)

- Service floors and ladders (K)

- Building Markup and Inspection (M)

- Site work execution program (X)