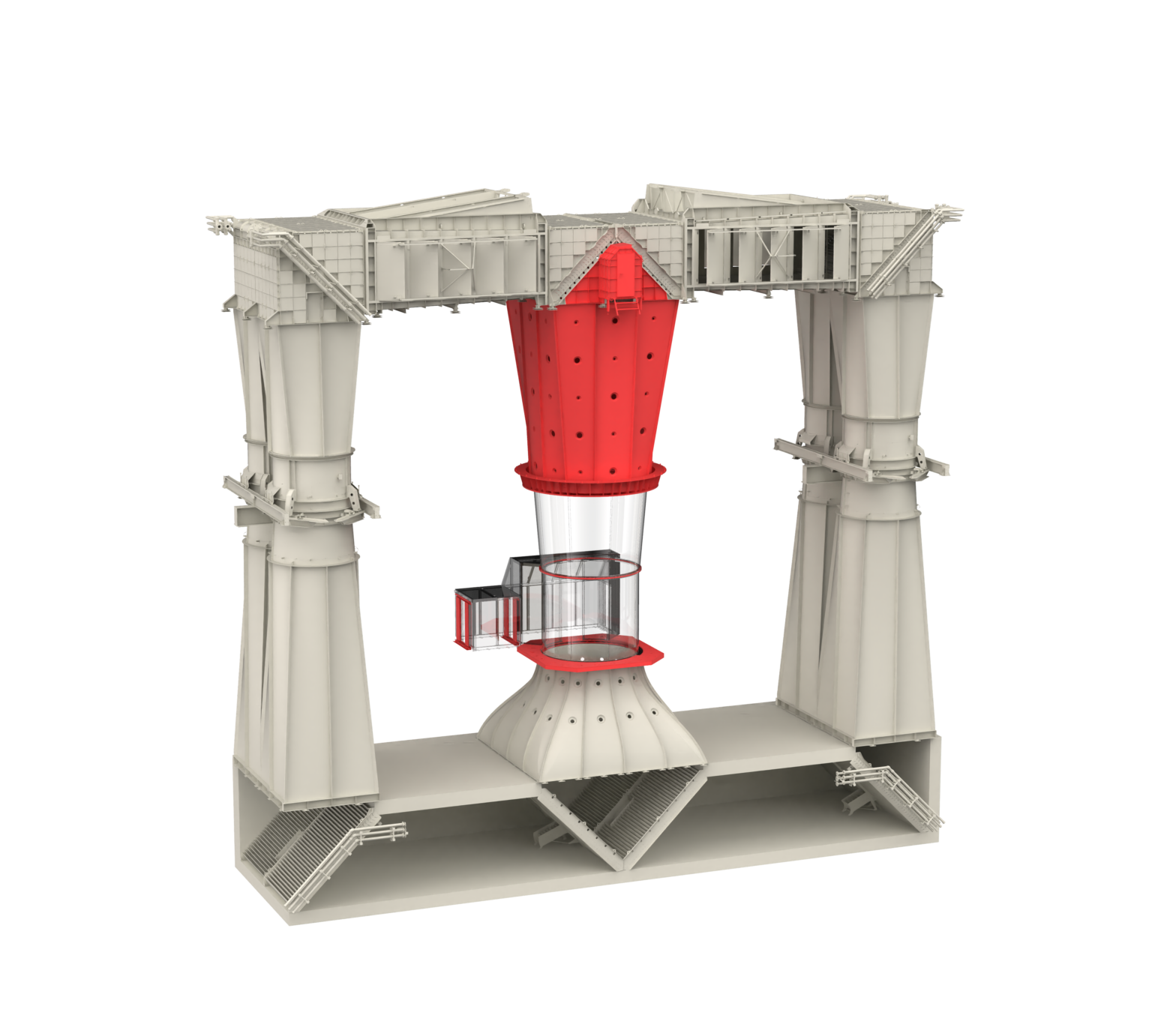

- Revolutionary safety net made of low-drag steel cables absorbs the impact force where it’s needed the most – at the outer edge of the flight chamber

- Padded entrance prevents traumatic injuries even during high-speed collisions and maintains even airflow in the chamber.

- TT signature conical glass frameless section, allowing for twice as much visible flying space with no compromise on safe speed reduction*

- Perfectly round multilayer noise-absorbing glass provides even airflow unlike polygonal flight chambers and noise-free experience for spectators.

* Critical safety feature eliminating high-speed accidents possibility. Speed difference between the levels of Safety net and below 1-st turning vane

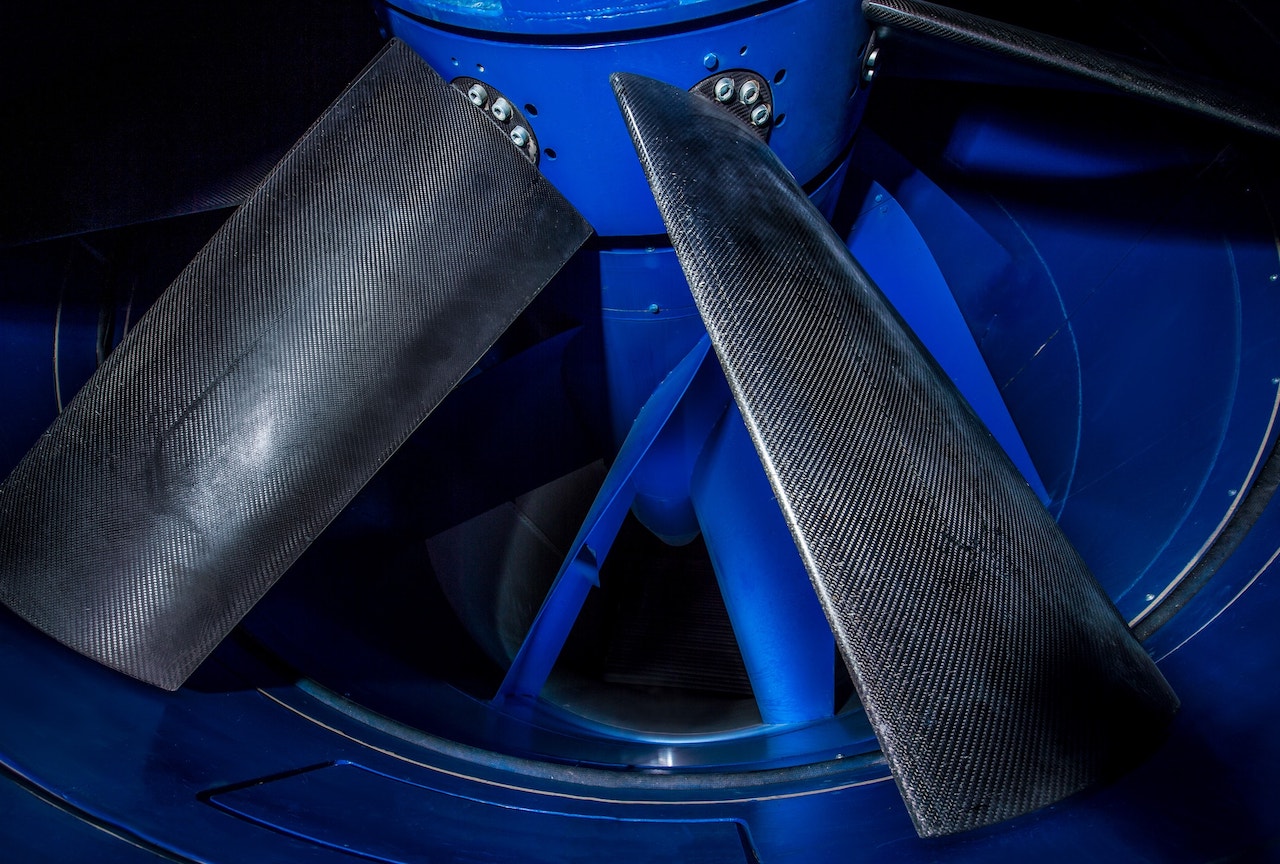

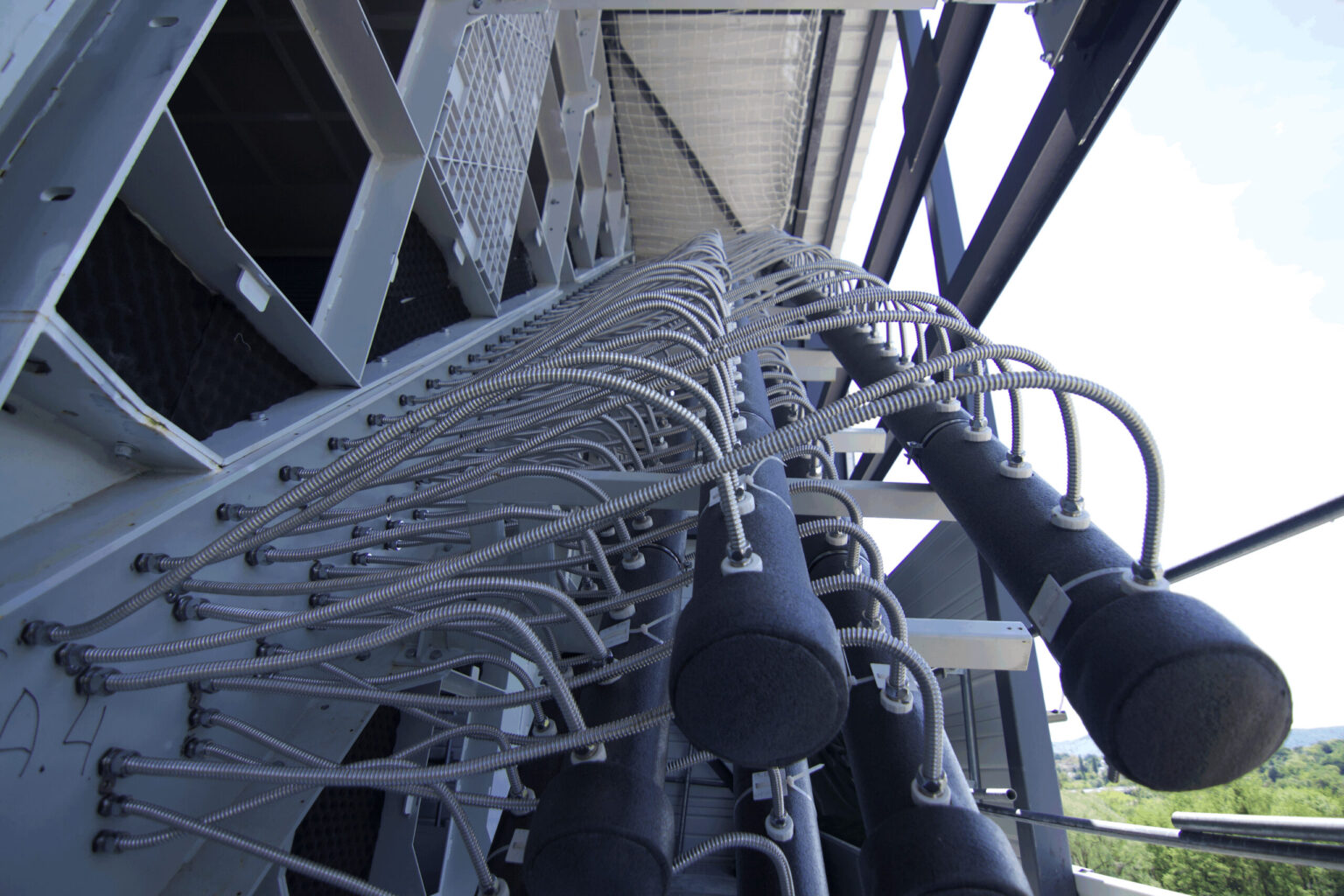

Axial Fans

The strategic alliance with EVG Lufttechnik, German manufacturer of special industrial fans with over 40 years of experience in aerodynamics and production, provides know-how and a solid basis for company, product and project development and gives us the opportunity to offer our customers the best, most efficient and safest wind tunnels currently available. For skydiving wind tunnel fans, EVG introduced carbon fiber blades that – in terms of power, efficiency and flow quality – take each of our tunnels to a completely new level. Thanks to the large diameter and low RPM, our fans deliver excellent airflow quality with minimal noise and vibration. Being powered by either ABB or Siemens electric motors, these fans make the most reliable wind machines on the market with expected life span of 30+ years.

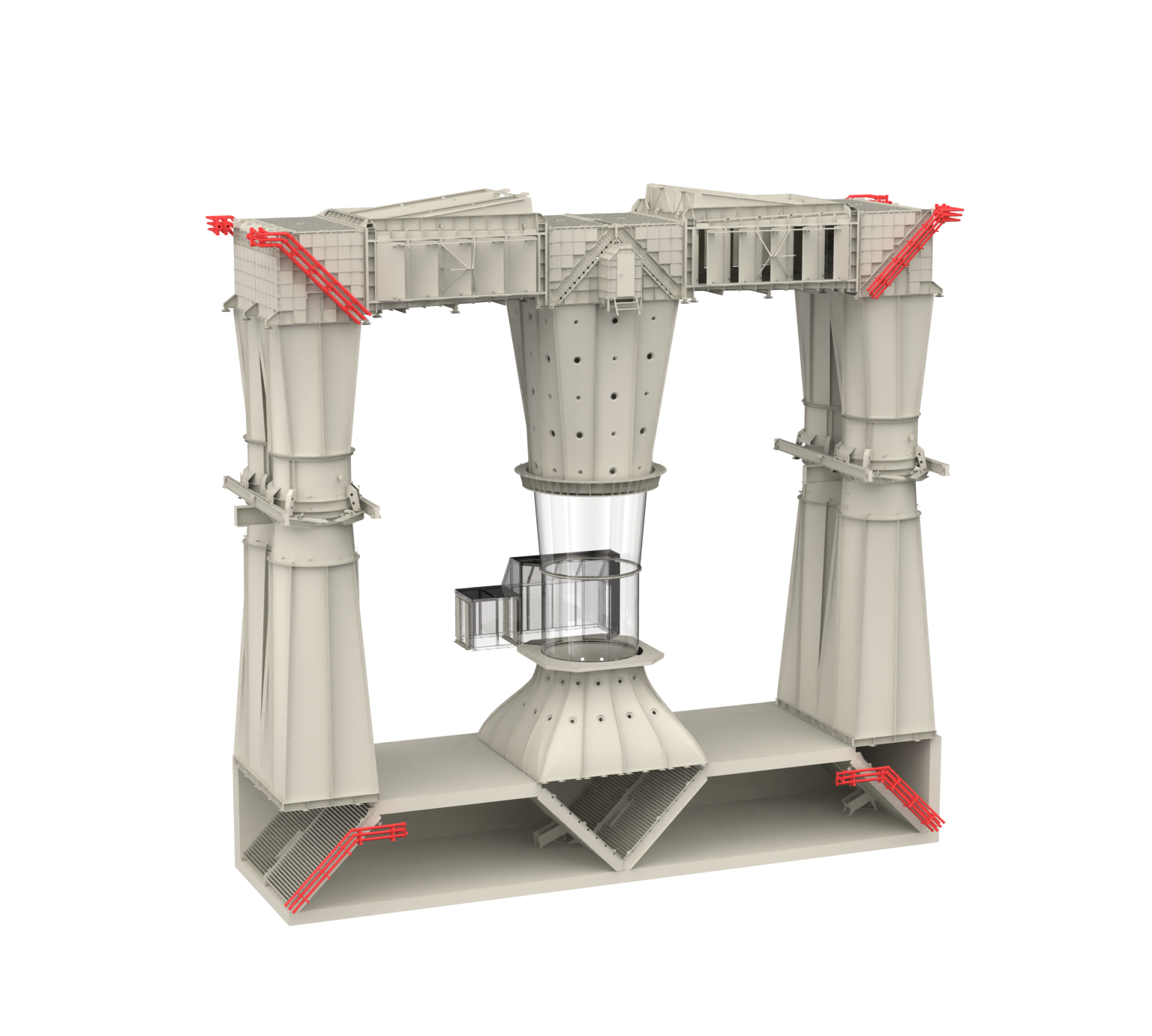

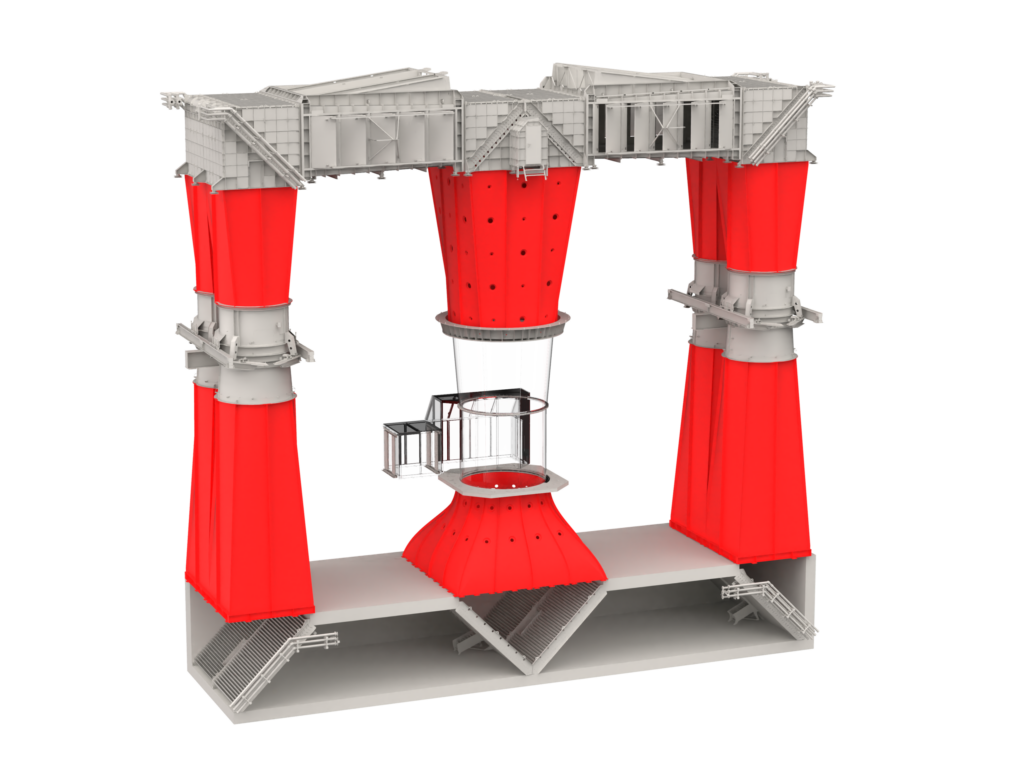

FRP Composite Airducts

Just like every exceptional sailboat is built around perfect streamlined shape wind tunnel’s efficiency relies upon honed aerodynamic lines to guide unobstructed airflow from the motors to the flight chamber and back. For this simple yet challenging task we utilised hi-end technology proven by decades of racing speedboat design and construction.

Our FRP Composite Air Ducts made with highest degree of precision ensure smooth transitions between each part of the tunnel. Unlike metal and concrete FRP air ducts:

- Allow for more precisely shaped form and eliminate near wall turbulence – the primary cause of noise & vibration emissions, bringing wind tunnels to more demanding locations (e.g. shopping centres, or in proximity residential areas).

- Have sandwich structure absorbing sound waves rather than transmitting them down the loop and resulting in uncontrolled resonance peaks common for conventional air ducts, making flying pleasant and safe for children and staff.

- Improve overall aerodynamic design, therefore energy efficiency of the tunnel, significantly reducing operating costs and cooling expenses.

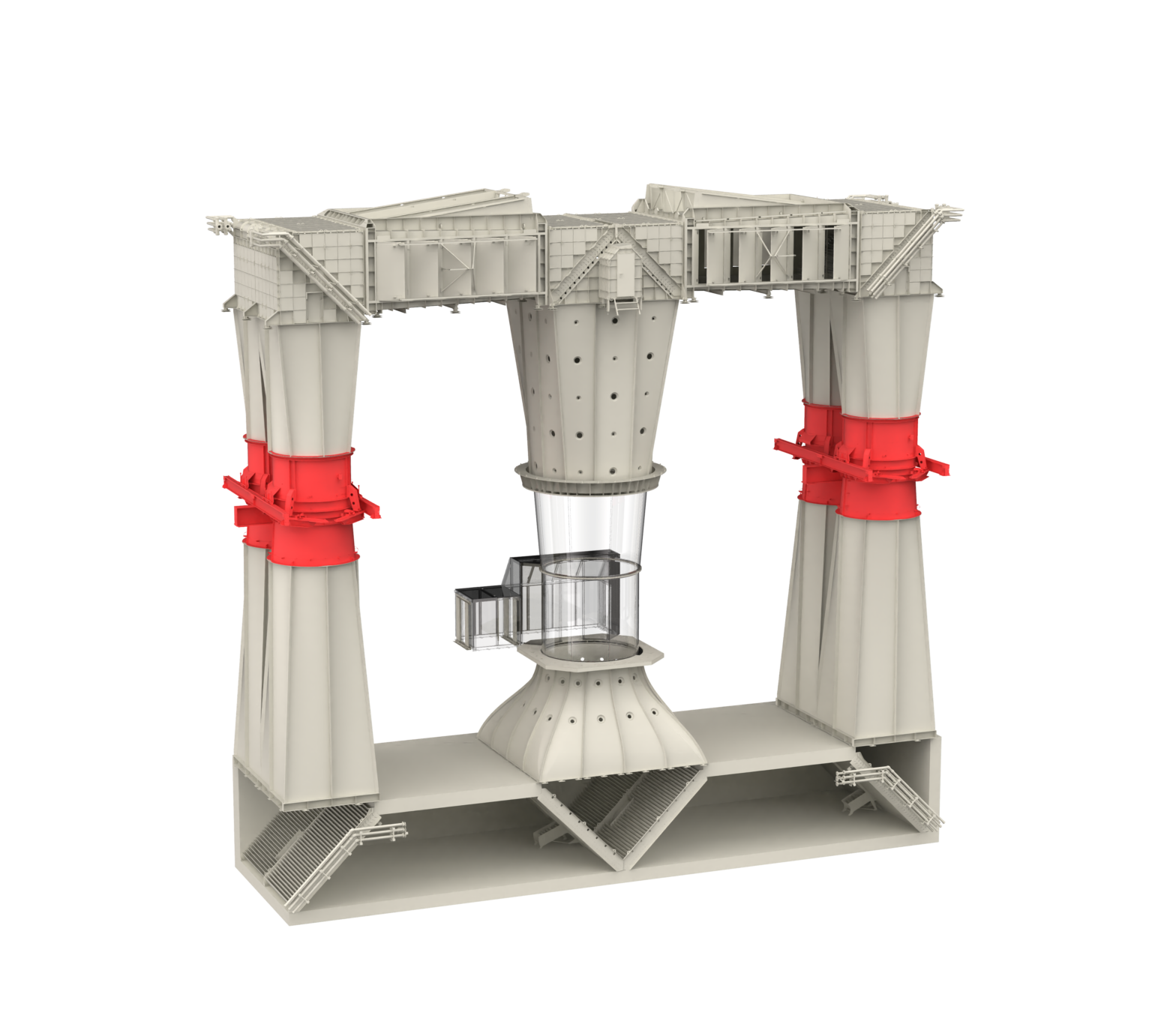

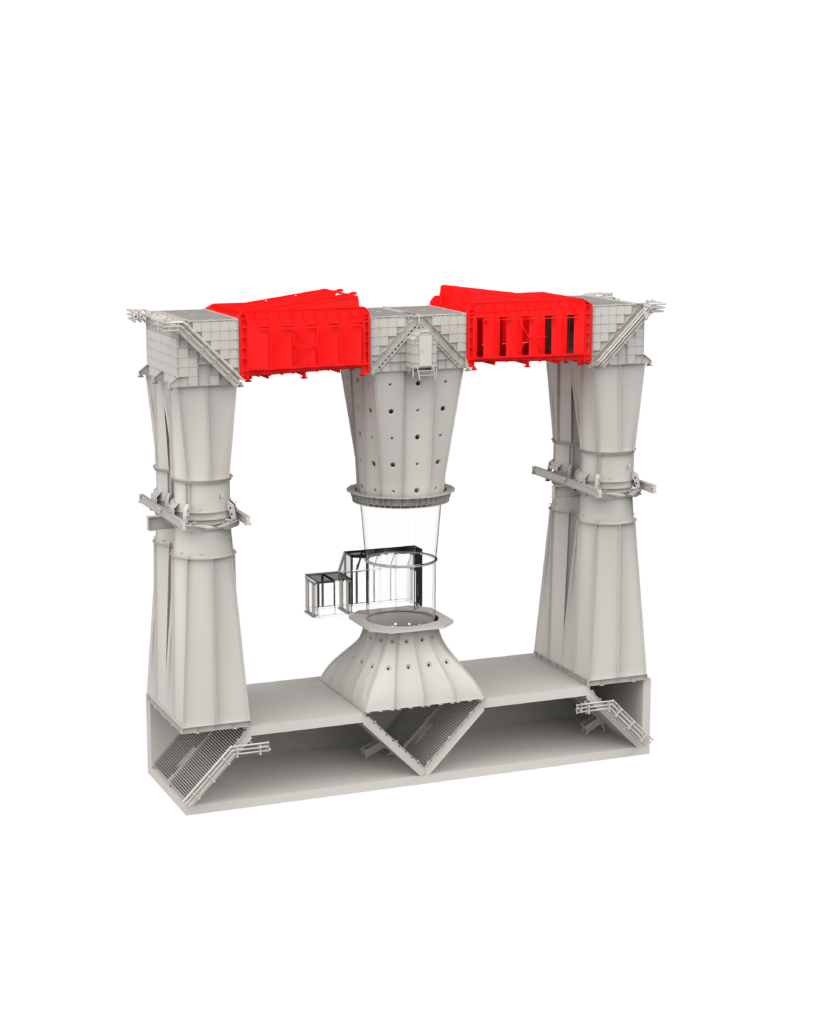

Turning Vanes

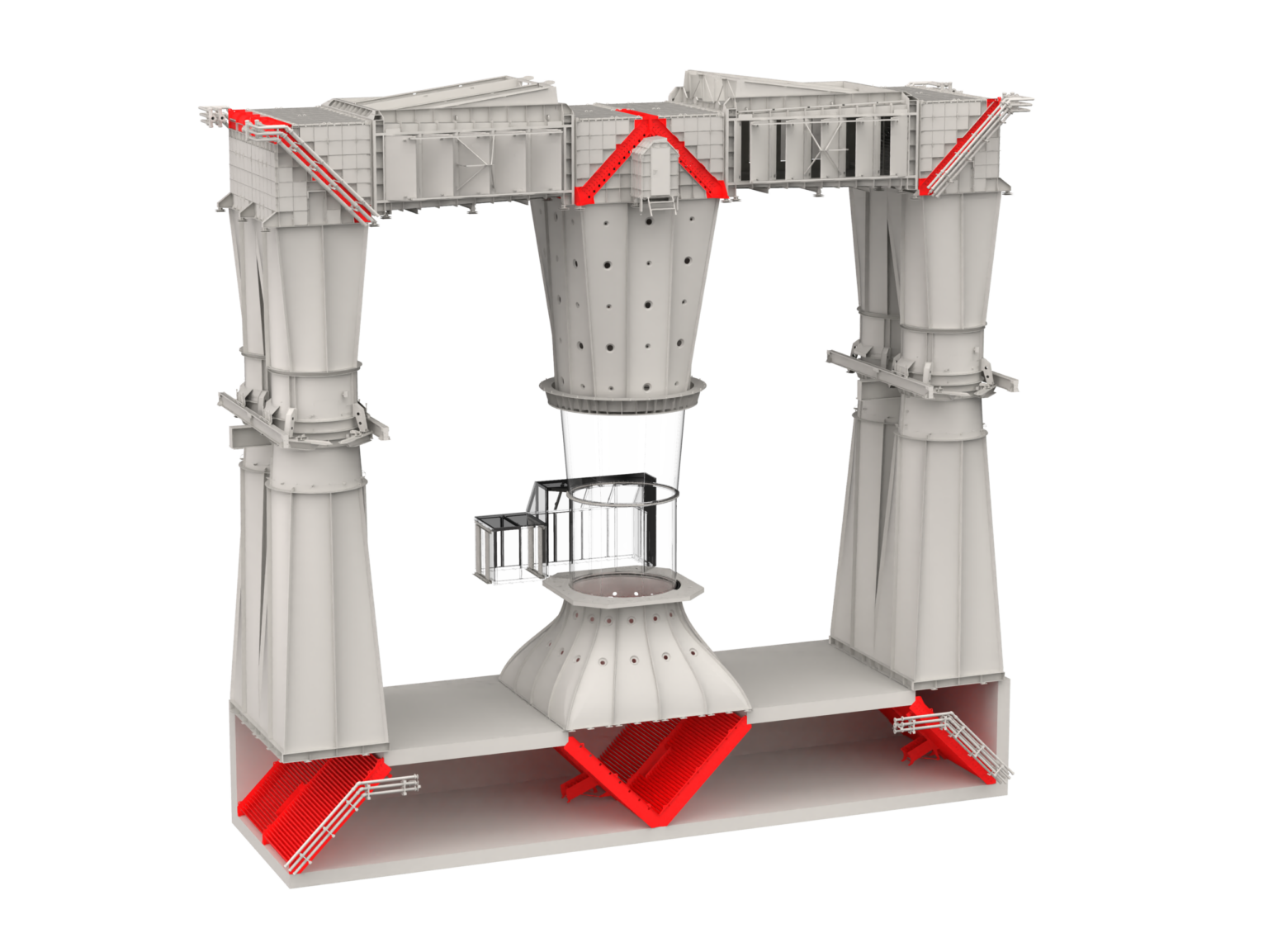

Climate Control

Ventilation

Our wind tunnels are equipped with outright ventilation that provides effective air exchange and airflow cooling without additional costs associated with HVAC appliance. Ventilation louvers replace up to 20% of circulating airflow volume with fresh air efficiently cooling the system in outside temperatures below 30C° leading to total energy consumption reduced by up to 30%.

For hot climates, and to reduce noise levels, we recommend the addition of an Active Cooling System.

Wind tunnel with cooling system can be operated in any extreme climates and virtually inaudible from the outside making it possible for the facility to be located in close proximity to residential areas or any others where outside noise emissions are undesirable

Active Cooling System

TunnelTech cooling system relies on uniform airflow cooling via turning vanes assembly. Unlike other wind tunnel technologies in our tunnels cooling fluid is supplied from centralised HVAC systems directly in to the hollow turning vanes acting as heat exchangers. This approach eliminates turbulence occurring if cooled air is injected in the airflow with conventional style systems.

Additional Options

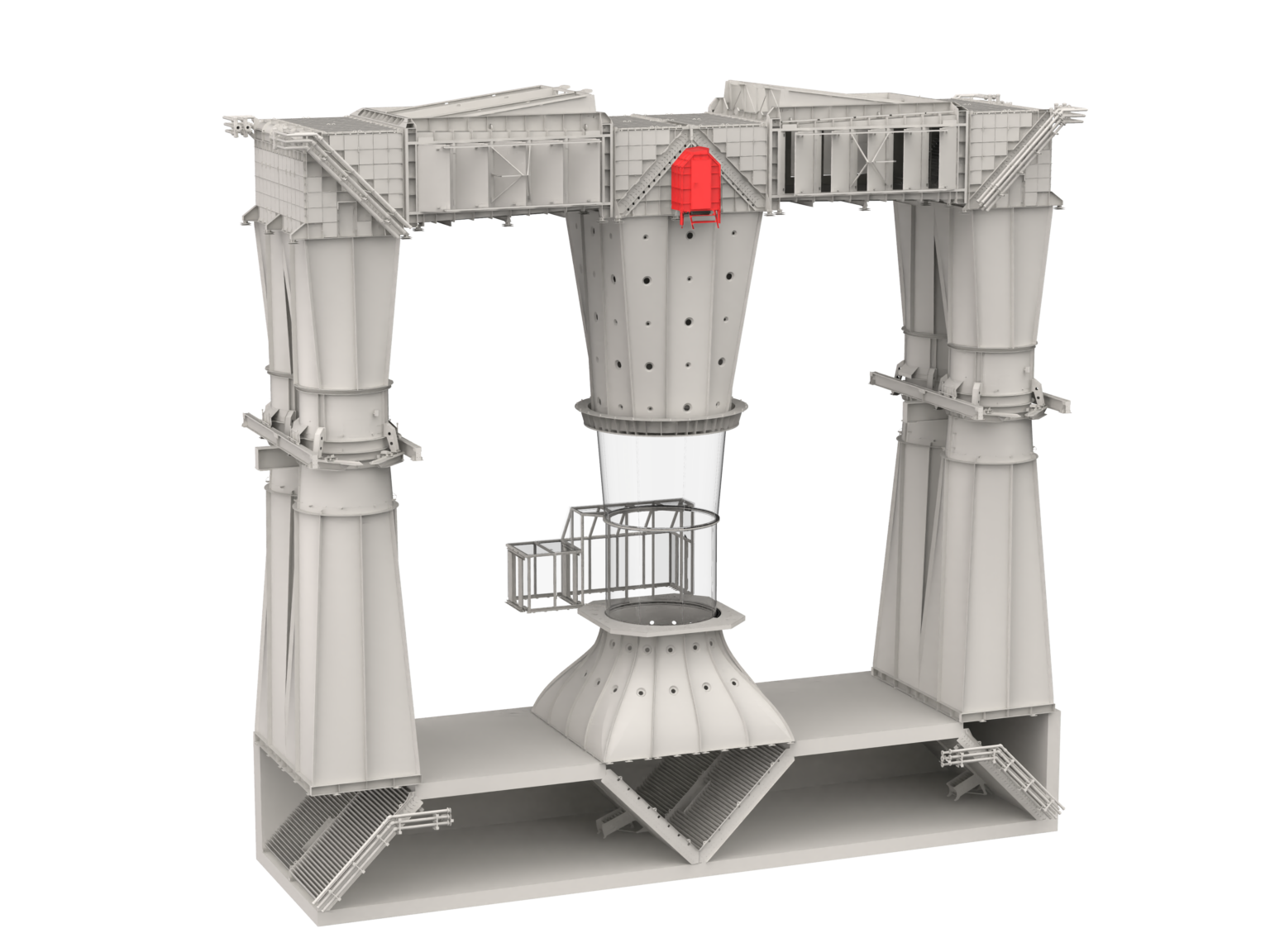

BASE Jumping Chamber

Located at the top of a wind tunnel so-called BASE-chamber is an essential tool for professional skydiving training, technically it is another entrance to the flight chamber making it possible to practice controlled aircraft exit. Due to 2x windspeed reduction at the door TunnelTech’s BASE-chamber is the only one suitable for training with stabilising parachute significantly improving safety of such training. On demand, base chamber may be decorated with aircraft interior and equipped with comprehensive set of automations and safety systems.