Overview

Currently the second largest in the world, TT65 PRO is the biggest wind tunnel among economically feasible ones. Its exceptional size and innovative design can accommodate larger teams and more complex manoeuvres, allowing athletes to push the boundaries of their skills and showcase the true potential of indoor skydiving. Oriented to prestige projects, where business is secondary to vision opportunity and publicity. Best for government ventures aiming to leave a long-lasting legacy.

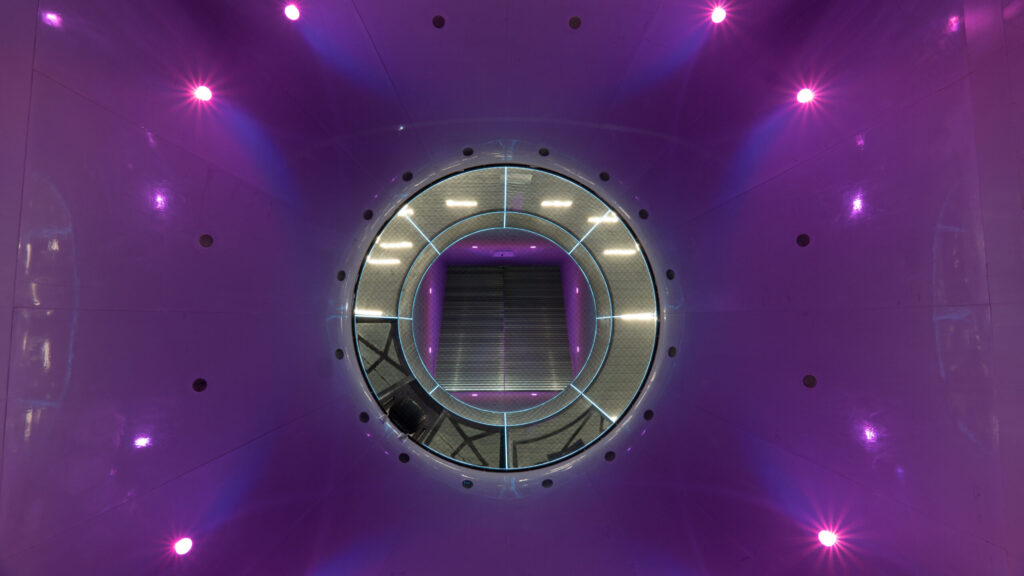

The impressive 6.5-meter-diameter flight chamber makes TT65 PRO an ideal venue for world championships and other high-class indoor skydiving sport events. 10 meters of frameless chemically strengthened glass allow superb transparency and extreme reliability. The glass section is divided into two equally tall levels: the bottom one is cylindrical while the upper one is conical.

To maximize the power and make this wind tunnel suitable for advanced military training, TT65 PRO is equipped with 6 extra-large axial fans with carbon fiber blades. Positioned in the vertical air ducts, the axial fans provide the necessary power without compromising energy efficiency and generating more noise. As a result, despite its size TT65 PRO is an environmentally friendly solution with reduced operating costs. Moreover, the minimal noise emissions make it possible to incorporate TT65 PRO into challenging settings.

As all the wind tunnels by Tunnel Tech, TT65 PRO features a list of important safety enhancements. 1.5 flight chamber diffusion ratio, specially designed safety net with near-the-wall deflection, and a curved flight chamber portal prevent injuries even during the most extreme activities.

For the comfort of the flyers, TT65 PRO’s design includes both an outright ventilation system and an optional active cooling system. The ventilation ensures power-efficient operation whenever the outside temperatures are below 30°C adding up to 35% to energy savings. The hollow turning vanes are used for turbulence-free cooling in hot climate zones. None of the systems affect the airflow quality, thus allowing the best performance with maximum comfort.

TT65 PRO stands as an exceptional solution, tailored to meet the demands of the most ambitious and visionary projects. Whether you’re envisioning a large-scale entertainment complex, a world-class sports training facility, or a cutting-edge military training centre, TT65 PRO is your reliable choice in turning ambitious ideas into remarkable realities. It unlocks opportunities for creativity, performance, and safety that were previously out of reach, ensuring that your venture will set new standards and leave a lasting impact.

Specification

| Flight сhamber inner diameter | 6.5 m (21’4″) |

| Glass height default | 18m (59′) |

| Glass height maximum | 36 m (118’11”) |

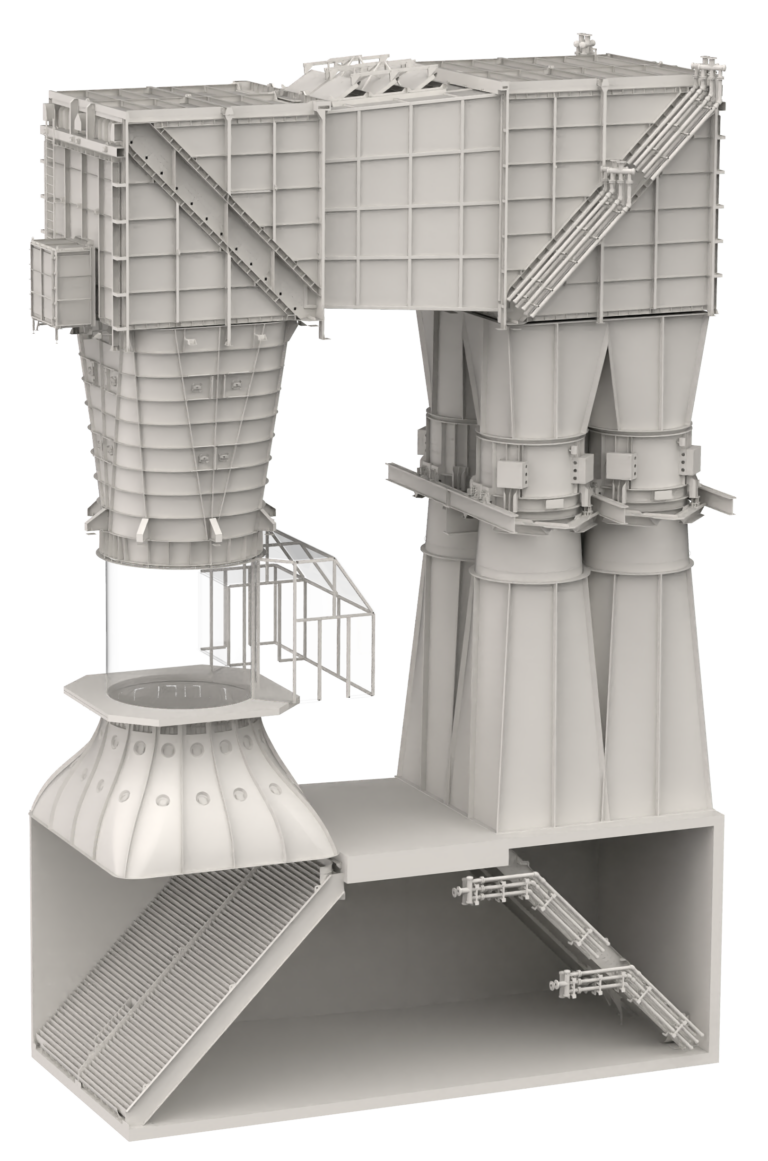

Dimensions Double Loop

| Height | 37.7 m (123’7″) |

| Length | 38.3 m (41’5″) |

| Width | 14 m (45’9″) |

Dimensions Single Loop

| Height | 45 m (147’6″) |

| Length | 30 m (98’4″) |

| Width | 12 m (39’4″) |

| Power capacity (min) | 3360 kW |

| Average time-weighted power consumption | 1171 kW |

| Power consumption @ 180 km/h | 857 kW |

| Standard power capacity | 3360 kW |

| Advanced power capacity | n/a |

| Beast power capacity | n/a |

| Noise level | 60 dBA (optional) |

| Darcy-Weissbach drag coefficient, Xi | 0.27 |

| Max. Speed @ Standard power capacity | 275 km/h |

| Max. Speed @ Advanced power capacity | 290 km/h |

| Diameter | 6.5 m (21’3″) |

| Height (minimum) | 21.5 m (70’5″) |

| Area | 33.16 m (108’8″) |

| Default glass height | 18 m (59′) |

| Glass type | chemically strengthened, non-shattering |

| Glass total thickness | ≥50 mm |

| Low iron glass | yes |

| Optional maximum glass height | up to 36 m (118’11”) |

| BASE jumping chamber height | 19 m (62’3″) |

| Patented safety net | maintains long stroke in close proximity to the walls |

| Safety net tensioner | 2 per cable |

| Speed drop (Diffusion rate) | 1.47 |

| Portal entrance shape | curved, collision safe |

| Portal entrance material | impact-dampening rubber |

| Entrance area speed drop | ≤1% |

| Airlock doors | automated |

| Airlock emergency exit | yes |

| Smooth decompression | yes |

| Transit time of customer groups to/from the flight chamber | <1 min |

| Supplier | Tunneltech , Germany |

| Quantity | 6 |

| Power (per fan) @ Standard power capacity | 560 kW |

| Power (per fan) @ Advanced power capacity | n/a |

| Location | return vertical airduct |

| Axel orientation | vertical |

| Diameter | 3.37 m (11′) |

| Effective crossectional area | 7.68 m (25’2″) |

| Blades material | carbon fibre |

| Blades count | 8 |

| Automated lubrication | yes |

| Material of FC Airjet (FC Contraction) | FRP |

| Material of FC Diffuser | glass |

| Material of return vertical airducts | FRP/steel |

| Ventilation (a.k.a. Passive Cooling) | yes |

| Max ventilation to airflow ratio | custom |

| Active Cooling System | yes (optional) |

| Additional drag, caused by active cooling system | 0 Pa (No drag) |

| Active Cooling type | through turning vanes |

| Recommended Chiller Cooling Capacity | 2400 kW (8,189,140 BRU/h)) |

| Color LED backlight strips between glass panels | yes, flicker-free (optional) |

| LED Strips power per m | 10 W |

| LED Strips frame rate | 60 fps |

| LED Projectors | yes, flicker-free (optional) |

| LED projectors default number installed (optional) | 8 – 32 (optional) |

| LED projectors max. power | 90 W |

| LED projectors max. luminous flux power | R:1950 G:2700 B:750 lumen |

| LED projector dimming capability | 0 – 100% |

| LED control from Main Panel | yes |

| LED anti-flicker function | high frequency PWM |

| LED projector PWM frequency | 1 kHz |

| LED color depth | 24 bit, 16,777,216 colors |

| LED projector color depth | 36 bit, 64 bln colors |

| Main panel control display | 28″ |

| Touch screen main panel | yes |

| Flight chamber info display | 31.5″ |

| Operator desk speed controller | autonomous knob |

| Waiting zone speed controller | autonomous knob |

| Base chamber speed controller | autonomous knob |

| Speed controller knob resolution | 0,1% |

| Chord | 500 mm |

| Chord-to-Spacing ratio | ≥3:1 |

| Material | aluminium |

| Surface treatment | anodized |

| Cooling channels | 6 |

| Turning vane heat transfer ratio, per meter @ 10-35m/s airflow speed | >105 (±15) W/(m*K) |

TT65Pro Double loop (PF65DL)

PF65DL Technical Documents (full version). The full technical documentation is available upon request. Please contact us.

Document archive contents:

- Building Requirements (A)

- Wind tunnel equipment location (T)

- Equipment loads (E)

- Equipment bases tolerance requirements (H)

- Cooling System (C)

- Cable networks (P)

- Service floors and ladders (K)

- Building Markup and Inspection (M)

- Site work execution program (X)

TT65Pro Single loop (PF65SL)

PF65SL Technical Documents can be developed on request.

Please see PF65DL model documentation.