Overview

TT45 PRO. Ultimate flight machine

This time we’re actually going to say it… The TT45 is “state-of-the-art” indoor skydiving recirculating wind tunnel by TunnelTech, delivering top-notch airflow quality, lowest noise emissions ever and unseen, unrivalled energy efficiency. Numerous safety features pioneered in TT45 PRO provide unparalleled flying experience to professional flyers and first-timers alike. It is a result of 20+ years dedicated to skydiving, bodyflying, instructing and wind tunnel operations management, from flyers and tunnel owners to flyers and tunnel owners.

Lowest operating expenses among sportflyersfriendly projects. The most advanced wind tunnel on the market. Best value machine.

The most technologically advanced indoor skydiving recirculating wind tunnel on the market, TT45 PRO sets new standards in the industry. Providing 12% more space compared to 14ft tunnels with circular flight chamber, it delivers superb airflow quality, whisper-quiet operation and unseen energy efficiency. Numerous safety features pioneered in TT45 PRO provide unparalleled flying experience to first timers, professional flyers and specialized military training alike.

Designed to accommodate world-class indoor skydiving events, TT45 PRO is suitable for a wide range of disciplines, including dynamic ones: 4-way dynamic, 6-way formation skydiving and up to 24-way VFS head down formations. With a maximum wind speed of up to 320 km/h (optional) and a flight chamber diameter of 4.5 meters, it provides ample space and wind power for the most demanding athletes and teams.

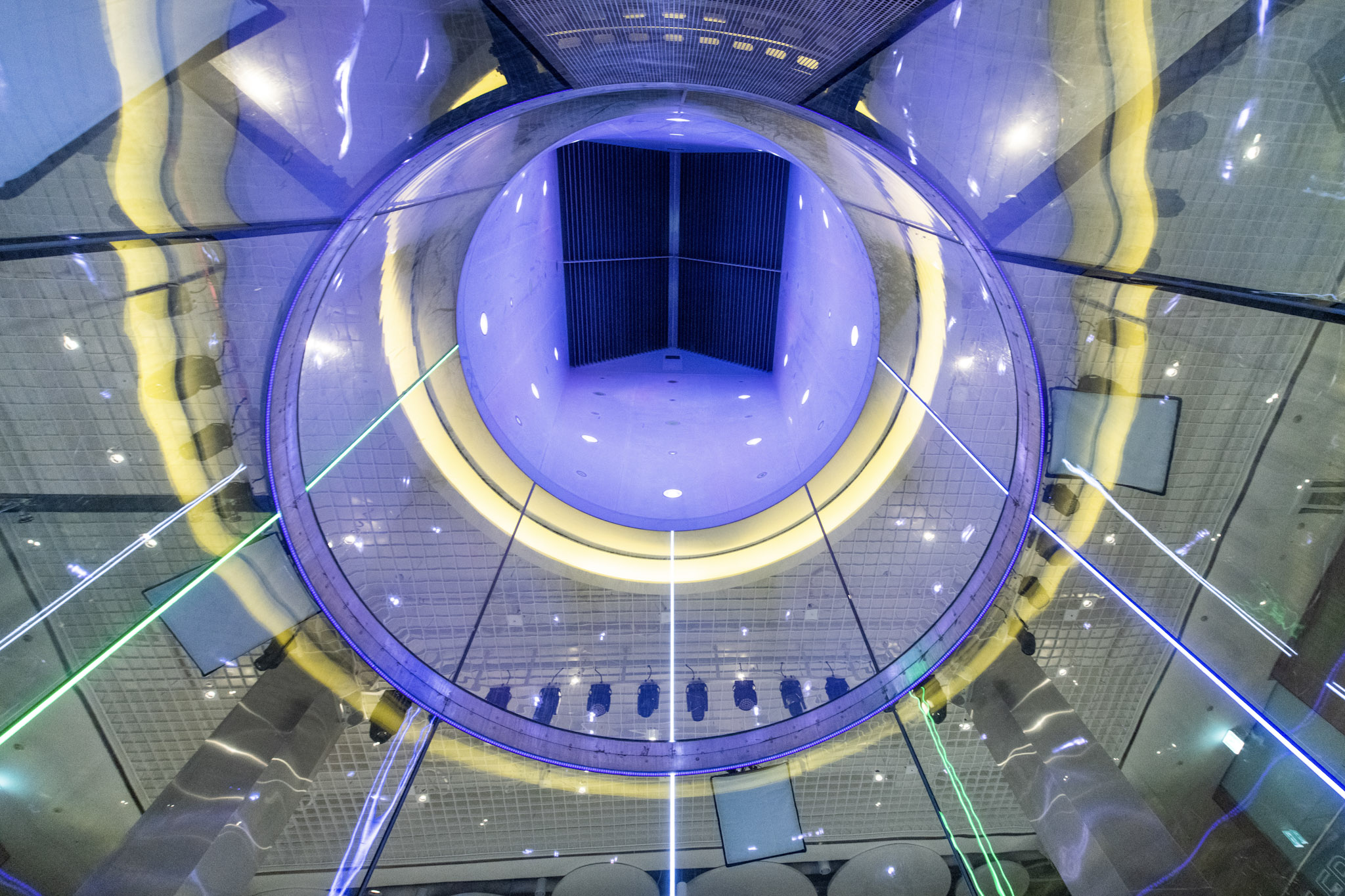

Its cutting-edge technology and design ensure that athletes can perform at their best, while spectators enjoy a thrilling and safe experience. The frameless 8-meter-tall glass chamber with a fully round cylindrical bottom level and an expanding conical second level provides enhanced visibility and flight monitoring. Opting for chemically strengthened glass helps avoid shattering even in case of collision with metal objects.

With a special focus on safety, TT45 features 2.1 flight chamber diffusion ratio, well-balanced safety nets with additional near-the-wall deflection, and a curved entrance to the flight chamber to avoid injuries, thus securing an enjoyable experience for novice and experienced flyers.

TT45 PRO is the most silent machine with astonishing 51dB(A) 1m in front of the flight chamber glass at belly speeds. Such minimal noise emissions allow to integrate TT45 PRO in close proximity or even within residential buildings, mixed use and retail developments.

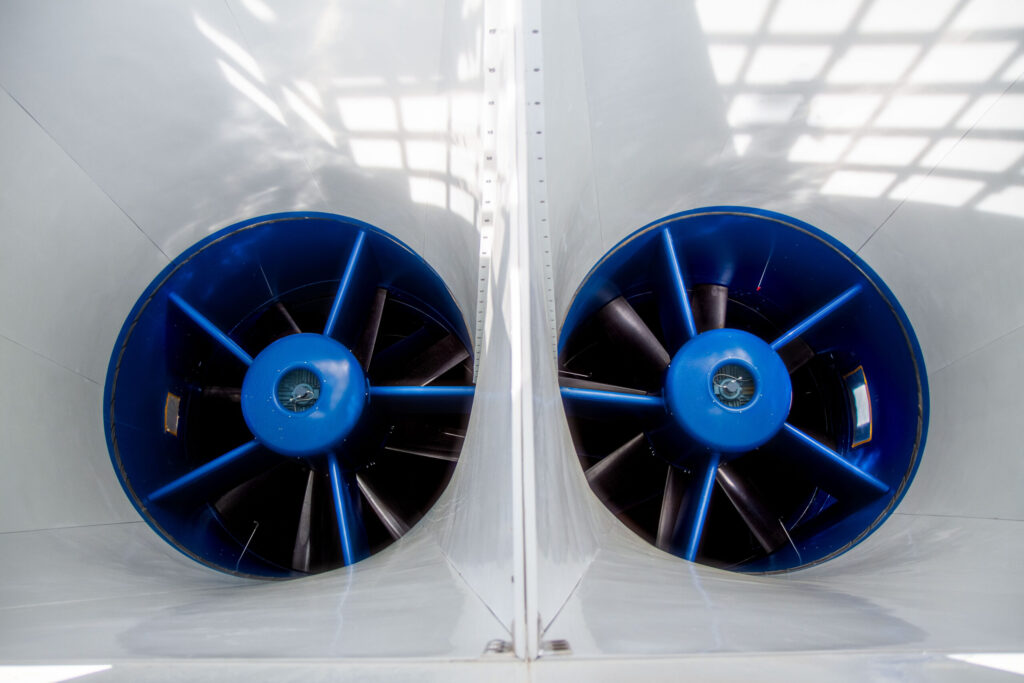

As energy consumption is a crucial factor in indoor skydiving projects, TT45 PRO boasts exceptional 255-300kW for the belly speed, ensuring lowest power consumption across 14ft class and minimal operating costs among sport flyers-friendly projects. High level of energy efficiency is granted by the overall design, which includes 4 extra-large axial fans with carbon fiber blades situated in the vertical airducts. This wind tunnel is ideal for countries with high energy costs and for environmentally conscious operators.

To ensure a comfortable environment for flyers, regardless of the weather outside, TT45 PRO is equipped with an outright ventilation system and an optional active cooling system. For mild and cold climate locations, outright ventilation allows to additionally increase energy savings up to 35%. For hot climate zones turbulence-free cooling is provided through the hollow turning vanes.

Investing in a TT45 PRO wind tunnel ensures a future-proof, world-class indoor skydiving experience for both entertainment and professional flyers. Its advanced safety features, exceptional performance, and outstanding energy efficiency make it the ultimate choice for any project, from shopping malls to dedicated skydiving centres.

Specification

| Flight сhamber inner diameter | 4.5m (14’9”) |

| Glass height default | 8 m (26’2″) |

| Glass height maximum | 16 m (52’5″) |

Dimensions Double Loop

| Height | 30.6 m (100’4″) |

| Length | 33.8 m (110’9″) |

| Width | 10 m (32’8″) |

Dimensions Single Loop

| Height | 39.4 m (129’2″) |

| Length | 25.9 m (85′) |

| Width | 10.5 m (34’4″) |

| Power capacity (min) | 1260 kW |

| Average time-weighted power consumption | 384 kW |

| Power consumption @ 180 km/h | 278 kW |

| Standard power capacity | 1260 kW |

| Advanced power capacity | 1400 kW |

| Beast power capacity | 1600 kW |

| Noise level | 51 dBA |

| Darcy-Weissbach drag coefficient, Xi | 0.183 |

| Max. Speed @ Standard power capacity | 298 km/h |

| Max. Speed @ Advanced power capacity | 305 km/h |

| Max. Speed @ Beast power capacity | 320 km/h |

| Diameter | 4.5 m (14’8″) |

| Height (minimum) | 18 m (59′) |

| Area | 15.9 sq.m. |

| Default glass height | 8 m (26’8″) |

| Glass type | chemically strengthened, non-shattering |

| Glass total thickness | ≥50 mm |

| Low iron glass | yes |

| Optional maximum glass height | up to 16 m (52’5″) |

| BASE jumping chamber height | 18 m (59′) |

| Patented safety net | maintains long stroke in close proximity to the walls |

| Safety net tensioner | 2 per cable |

| Speed drop (Diffusion rate) | 2.12 |

| Portal entrance shape | curved, collision safe |

| Portal entrance material | impact-dampening rubber |

| Entrance area speed drop | ≤1% |

| Airlock doors | automated |

| Airlock emergency exit | yes |

| Smooth decompression | yes |

| Transit time of customer groups to/from the flight chamber | <1 min |

| Supplier | Tunneltech , Germany |

| Quantity | 4 |

| Power (per fan) @ Standard power capaccity | 315 kW |

| Power (per fan) @ Advanced power capacity | 350 kW |

| Power (per fan) @ Beast power capacity | 400 kW |

| Location | return vertical airduct |

| Axel orientation | vertical |

| Diameter | 3.37 m (11′) |

| Effective crossectional area | 7.68 sq.m. |

| Blades material | carbon fibre |

| Blades count | 8 |

| Automated lubrication | yes |

| Material of FC Airjet (FC Contraction) | FRP |

| Material of FC Diffuser | FRP or glass (optional) |

| Material of return vertical airducts | FRP |

| Ventilation (a.k.a. Passive Cooling) | yes |

| Max ventilation to airflow ratio | 30% |

| Active Cooling System | yes (optional) |

| Additional drag, caused by active cooling system | 0 Pa (No drag) |

| Active Cooling type | through turning vanes |

| Recommended Chiller Cooling Capacity | 900 kW (3,000,000 BTU/h) |

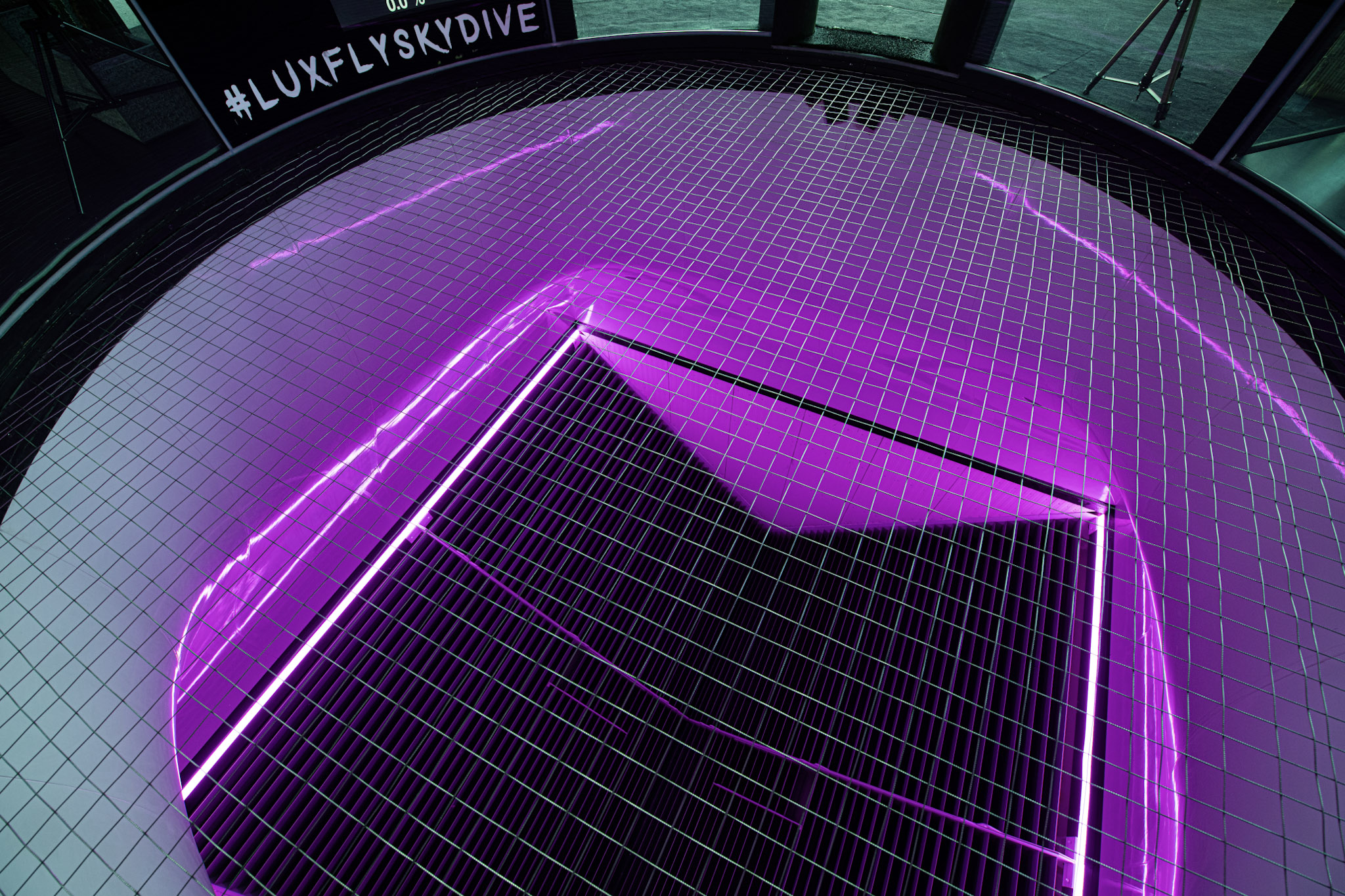

| Color LED backlight strips between glass panels | yes, flicker-free (optional) |

| LED Strips power per m | 10 W |

| LED Strips frame rate | 60 fps |

| LED Projectors | yes, flicker-free (optional) |

| LED projectors default number installed (optional) | 8 – 32 (optional) |

| LED projectors max. power | 100 W |

| LED projectors max. luminous flux power | R:1950 G:2700 B:750 lumen |

| LED projector dimming capability | 0 – 100% |

| LED control from Main Panel | yes |

| LED anti-flicker function | high frequency PWM |

| LED projector PWM frequency | 1 kHz |

| LED color depth | 24 bit, 16,777,216 colors |

| LED projector color depth | 36 bit, 64 bln colors |

| Main panel control display | 28″ |

| Touch screen main panel | yes |

| Flight chamber info display | 31.5″ |

| Operator desk speed controller | autonomous knob |

| Waiting zone speed controller | autonomous knob |

| Base chamber speed controller | autonomous knob |

| Speed controller knob resolution | 0,1% |

| Chord | 500 mm |

| Chord-to-Spacing ratio | ≥3:1 |

| Material | aluminium |

| Surface treatment | anodized |

| Cooling channels | 6 |

| Turning vane heat transfer ratio, per meter @ 10-35m/s airflow speed | >105 (±15) W/(m*K) |

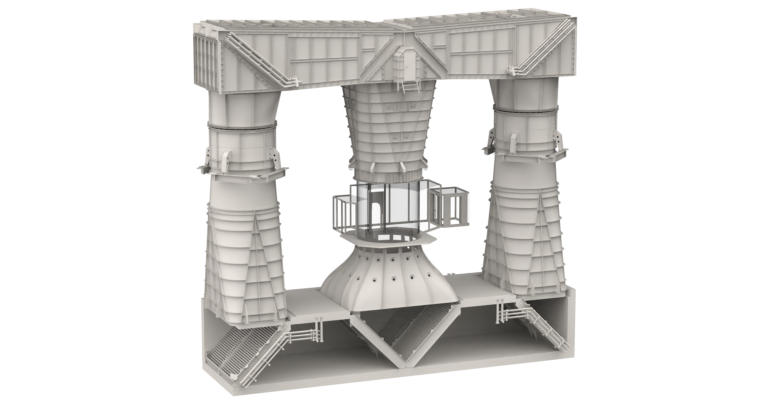

TT45Pro Double loop (PF45DL)

PF45DL Technical Documents (full version). The full technical documentation is available upon request. Please contact us.

Document archive contents:

- Building Requirements (A)

- Wind tunnel equipment location (T)

- Equipment loads (E)

- Equipment bases tolerance requirements (H)

- Cooling System (C)

- Cable networks (P)

- Service floors and ladders (K)

- Building Markup and Inspection (M)

- Site work execution program (X)

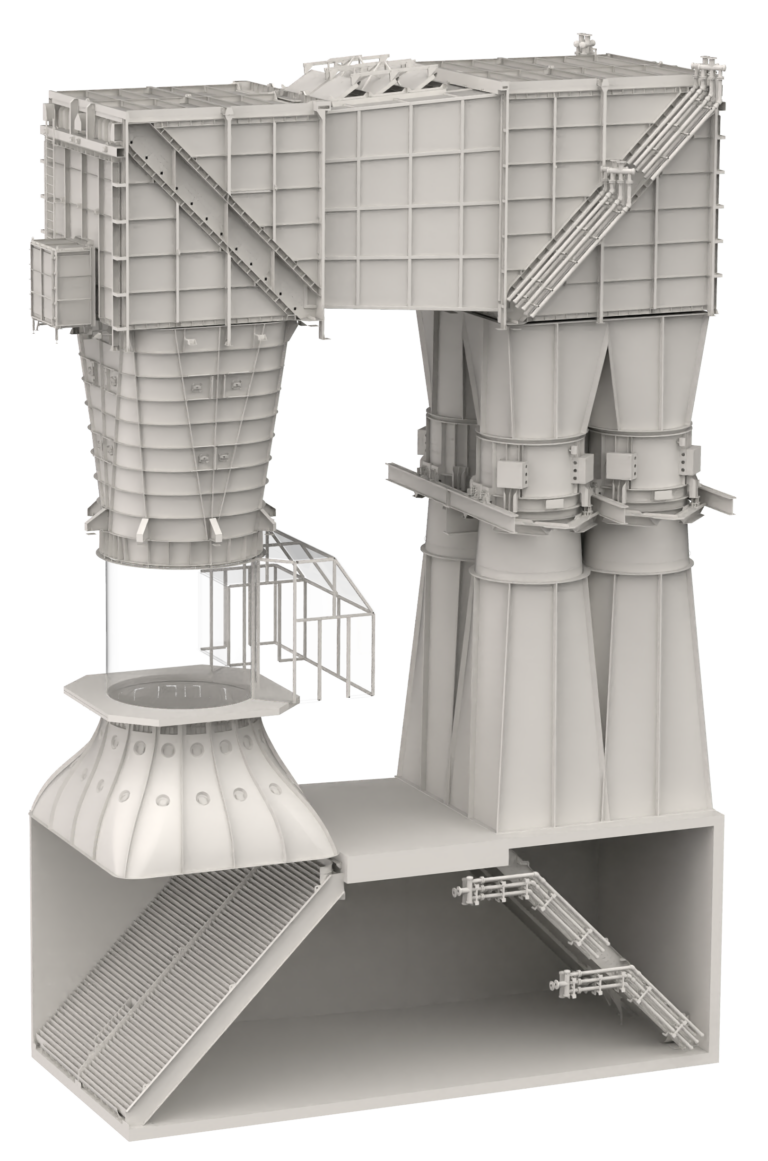

TT45Pro Single loop (PF45SL)

PF45SL Technical Documents (full version). The full technical documentation is available upon request. Please contact us.

Document archive contents:

- Building Requirements (A)

- Wind tunnel equipment location (T)

- Equipment loads (E)

- Equipment bases tolerance requirements (H)

- Cooling System (C)

- Cable networks (P)

- Service floors and ladders (K)

- Building Markup and Inspection (M)

- Site work execution program (X)