In the automotive realm, testing is paramount. A controlled environment where vehicles can be pushed to their limits, analyzed, and improved is a necessity. Recognizing this essential industry need, we at Tunnel Tech are poised and ready to deliver. While we’ve built our reputation on a plethora of successful tunnel constructions across varied sectors, the automotive domain presents unique challenges – challenges we’re eager and equipped to tackle.

Here’s why considering Tunnel Tech for your automotive tunnel needs is a logical step forward:

- Adaptable Expertise

Drawing from our vast experience in diverse tunnel projects, we’re primed to cater to the specificities of the automotive world.

- Unwavering Commitment to Safety

Our track record echoes our commitment to safety. We ensure that our structures stand resilient, safeguarding both personnel and equipment.

- Tailored Solutions

Understanding that no two testing needs are alike, we promise customization. Be it environmental simulations or specific vehicular requirements, our designs will mirror your needs.

- Compliance Ready

As industry norms evolve, so will our designs. We’re ready to ensure our tunnels meet and exceed any set standards.

- Resourceful and Innovative

Though new to the automotive sector, our innovative spirit and resourcefulness make us a worthy contender.

The automobile sector constantly strives for innovation, safety, and superior performance. Testing tunnels play an instrumental role in realizing these objectives, ensuring vehicles are efficient, safe, and reliable before they hit the roads. Here’s an insight into the importance of such testing tunnels and what they bring to the automotive world:

1. Simulated Real-World Conditions

Tunnels offer a controlled environment, where varied climatic and driving conditions can be simulated. From heavy rainfall and icy roads to scorching desert heat, these environments allow for comprehensive vehicle assessments.

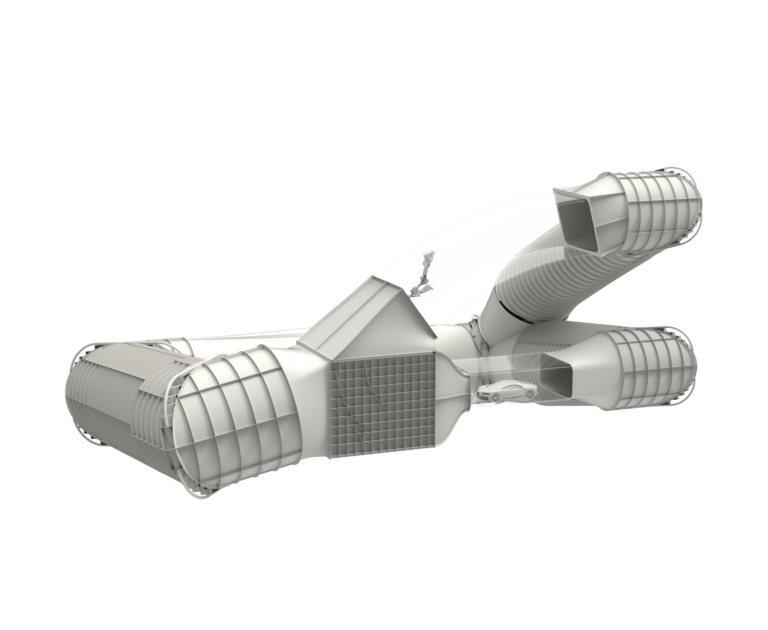

2. Aerodynamic Testing

By understanding how air flows around a vehicle, manufacturers can optimize designs for reduced drag, increased stability, and improved fuel efficiency. Tunnels equipped with advanced instrumentation provide insights into air resistance and pressure points.

3. Thermal Management

Extreme temperatures challenge a vehicle’s cooling systems, HVAC, and overall material durability. In testing tunnels, vehicles can be subjected to both hot and cold conditions, ensuring systems operate optimally and materials don’t degrade or fail.

4. Noise, Vibration, and Harshness (NVH) Assessment

Tunnels allow experts to study the noise levels inside and outside the car, vibrations in various components, and overall ride harshness. This ensures a comfortable and quiet ride for passengers and meets regulatory standards.

5. Emission and Pollution Testing:

As environmental regulations become stricter, tunnels provide a space to measure and analyze vehicular emissions under different conditions, ensuring vehicles are eco-friendly and compliant.

6. Safety Evaluations:

These controlled environments can be used to assess safety features, such as traction control, anti-lock brakes, and stability systems, under various conditions, ensuring vehicles react as intended during critical situations.

7. Endurance and Longevity Testing:

Tunnels allow for prolonged testing under controlled, repetitive conditions. This aids in identifying potential wear and tear issues and assessing the overall longevity of vehicle components.

8. Performance Optimization:

From acceleration and braking to maneuverability and fuel efficiency, tunnels enable exhaustive performance evaluations, ensuring vehicles deliver on promised specifications.