Overview

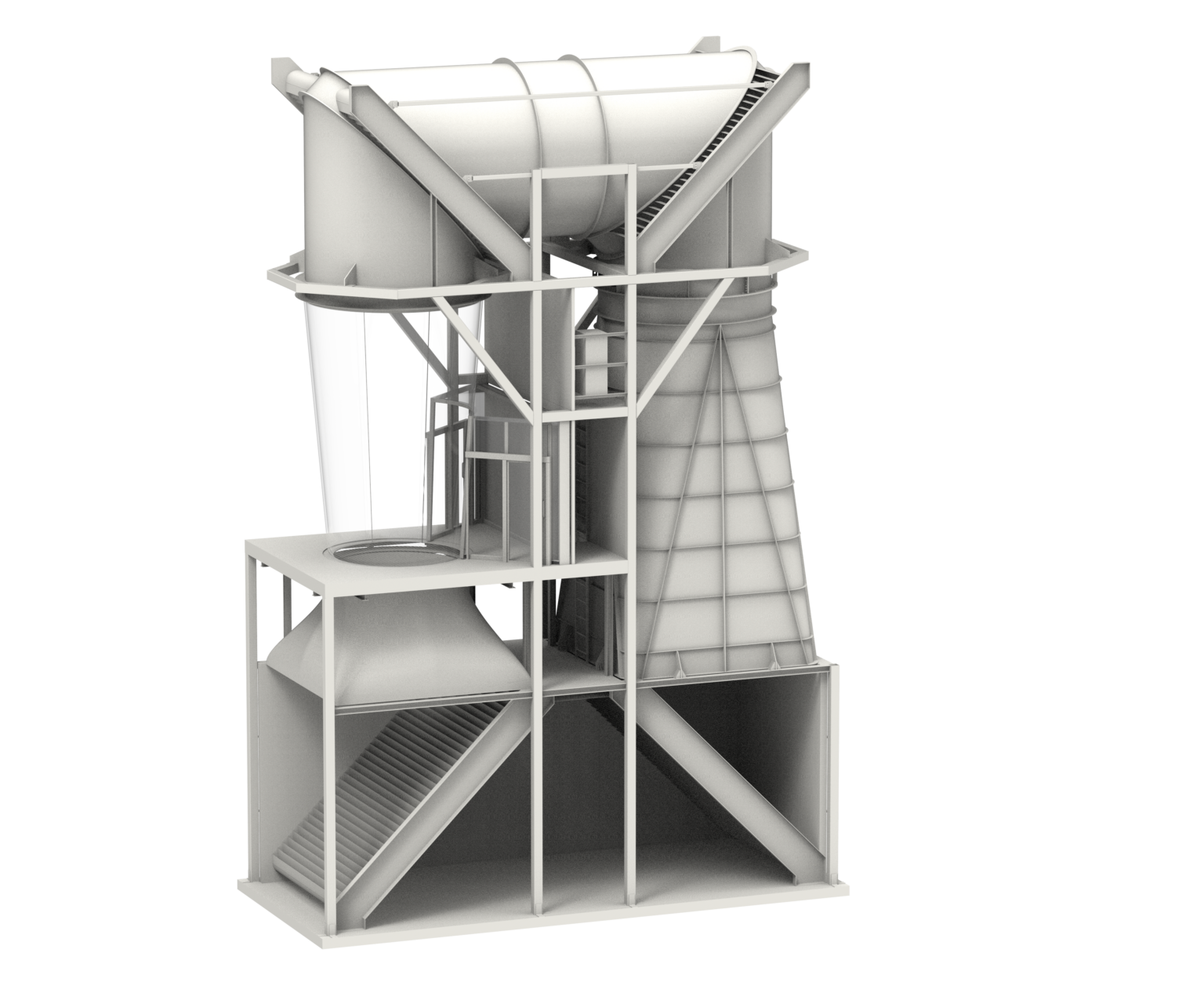

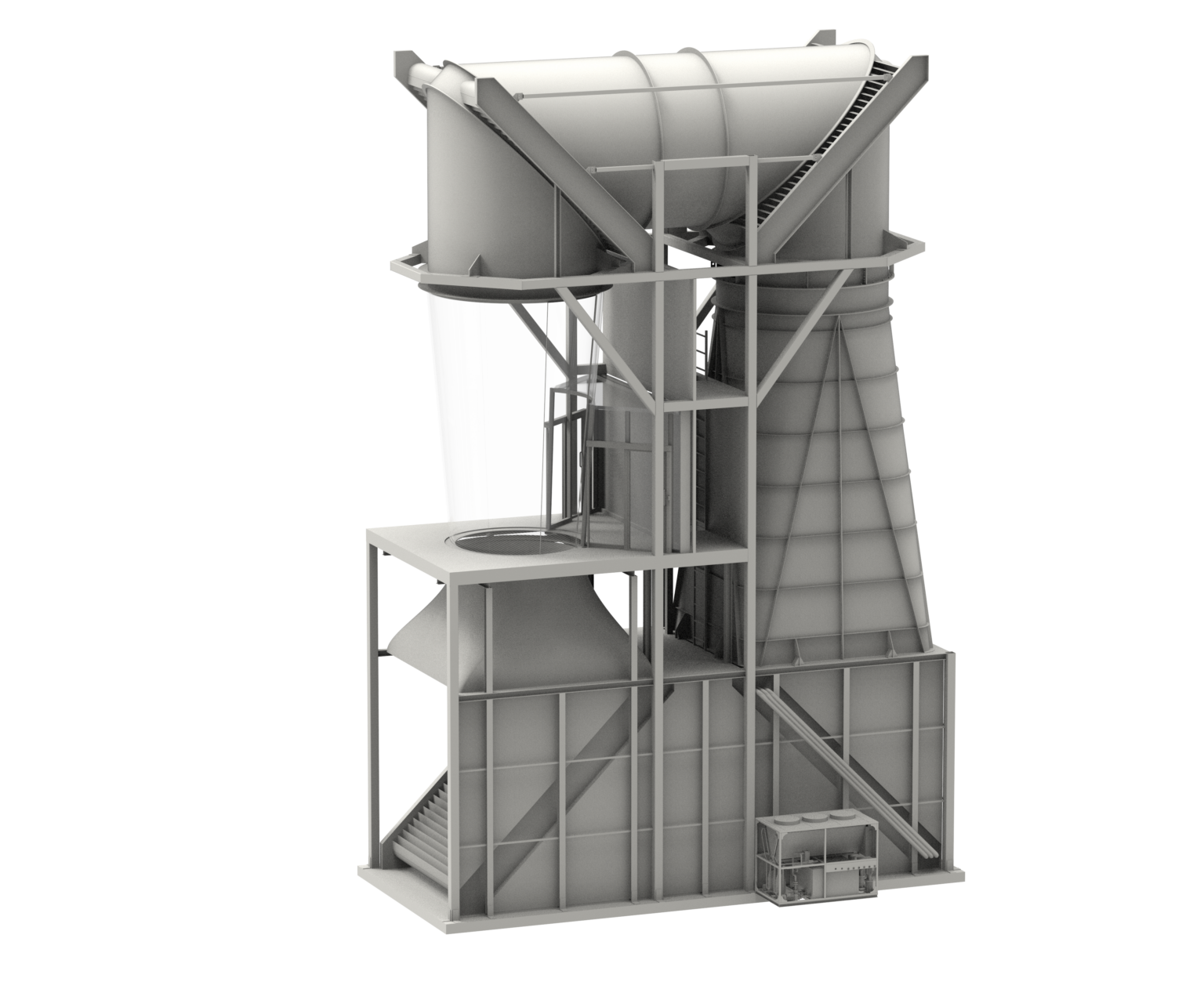

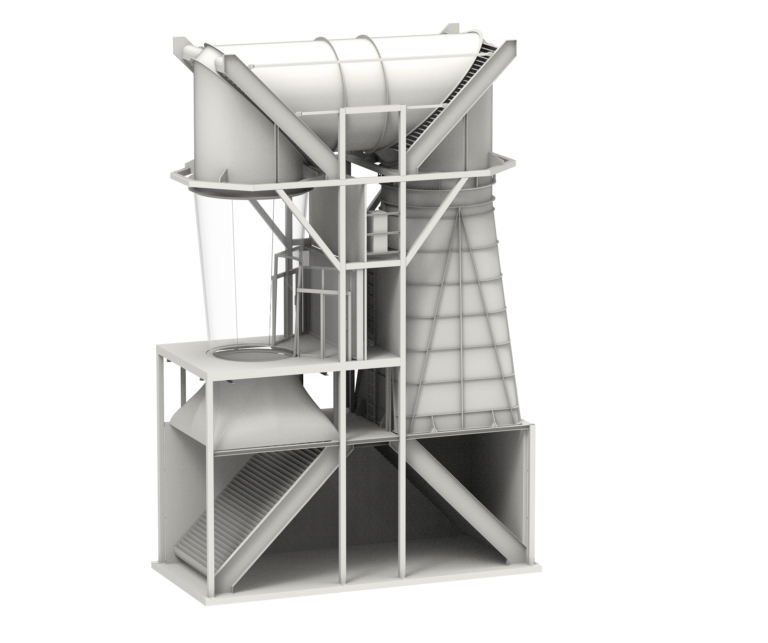

The smallest wind tunnel model in Tunnel Tech lineup, TT25 μFLY is an entry-level machine, tailor-made to meet the needs of entertainment-oriented projects. Overseeing the financial side was one of the priorities, while creating TT25 μFLY. The result is a remarkably affordable yet outstanding indoor skydiving solution that doesn’t compromise on quality. A perfect combination of high performance, compact footprint and low energy consumption.

Designed with first-timers as the main target group, TT25 μFLY features a cozy 2.5-meter diameter flight chamber. 5 meters of completely transparent chemically strengthened glass provide a safe environment inspiring to try body flying. The conical shape of the flight chamber optimizes safety and stability, allowing novice flyers to enjoy the experience with confidence.

Despite its size, TT25 μFLY is powerful enough for intermediate freefly training and head-up flying. As a result, it’s appealing for skydivers eager to hone their basic skills. This customer group can generate additional revenue in off-peak hours and increase the occupancy of the tunnel.

Featuring an extra-large low RMP axial fan with carbon fiber blades located in the vertical airduct, TT25 μFLY ensures high energy efficiency and low noise emissions. The built-in active cooling system provides turbulence free cooling through hollow turning vanes making the flying experience comfortable at any outside temperatures.

With the well-thought-out design installation and disassembly are straightforward. TT25 μFLY is your flexible, hassle-free solution for both permanent and temporary locations. TT25 μFLY arrives as a complete package, including a load-bearing structure and a chiller. It’s a plug-and-play solution, streamlining the setup process for your convenience.

TT25 μFLY allows to start generating returns swiftly. Our solution is crafted to minimize downtime and maximize profitability, ensuring that your investment pays off in record time. TT25 μFLY opens new opportunities for small-scale projects and economically challenging environments. Suitable for shopping malls, entertainment centers and amusement parks.

Specification

| Flight сhamber inner diameter | 2.5 (8′ 2″) |

Dimensions Single Loop

| Height | 16.5 m (54′) |

| Length | 10.7 m (35′) |

| Width | 4.7 m (15’4″) |

| Power capacity (min) | 450 kW |

| Average time-weighted power consumption | 199 kW |

| Power consumption @ 180 km/h | 146 kW |

| Standard power capacity | 450 kW |

| Advanced power capacity | n/a |

| Beast power capacity | n/a |

| Noise level | 65 dBA |

| Darcy-Weissbach drag coefficient, Xi | 0.31 |

| Max. Speed @ Standard power capacity | 250 km/h |

| Diameter | 2.5 (8′ 2″) |

| Height (minimum) | 5 m (16’4″) |

| Glass type | chemically strengthened, non-shattering |

| Glass total thickness | ≥50 mm |

| Low iron glass | yes |

| Optional maximum glass height | |

| BASE jumping chamber height | |

| Patented safety net | maintains long stroke in close proximity to the walls |

| Safety net tensioner | 2 per cable |

| Speed drop (Diffusion rate) | 2.12 |

| Portal entrance shape | curved, collision safe |

| Portal entrance material | impact-dampening rubber |

| Entrance area speed drop | ≤1% |

| Airlock doors | automated |

| Airlock emergency exit | yes |

| Smooth decompression | yes |

| Transit time of customer groups to/from the flight chamber | <1 min |

| Supplier | Tunneltech , Germany |

| Quantity | 1 |

| Power (per fan) @ Standard power capaccity | 450 kW |

| Location | return vertical airduct |

| Axel orientation | vertical |

| Diameter | 3.37 m (11′) |

| Effective crossectional area | 7.68 sq.m. |

| Blades material | carbon fibre |

| Blades count | |

| Automated lubrication | yes |

| Material of FC Airjet (FC Contraction) | FRP |

| Material of FC Diffuser | FRP or glass (optional) |

| Material of return vertical airducts | FRP |

| Ventilation (a.k.a. Passive Cooling) | yes |

| Max ventilation to airflow ratio | 30% |

| Active Cooling System | yes (optional) |

| Additional drag, caused by active cooling system | 0 Pa (No drag) |

| Active Cooling type | through turning vanes |

| Recommended Chiller Cooling Capacity | 450 kW (1,535,464.1 BTU/h) |

| Color LED backlight strips between glass panels | yes, flicker-free (optional) |

| LED Strips power per m | 10 W |

| LED Strips frame rate | 60 fps |

| LED Projectors | yes, flicker-free (optional) |

| LED projectors default number installed (optional) | 8 – 32 (optional) |

| LED projectors max. power | 90 W |

| LED projectors max. luminous flux power | R:1950 G:2700 B:750 lumen |

| LED projector dimming capability | 0 – 100% |

| LED control from Main Panel | yes |

| LED anti-flicker function | high frequency PWM |

| LED projector PWM frequency | 1 kHz |

| LED color depth | 24 bit, 16,777,216 colors |

| LED projector color depth | 36 bit, 64 bln colors |

| Main panel control display | 28″ |

| Touch screen main panel | yes |

| Flight chamber info display | 31.5″ |

| Operator Desk Speed Controller | yes |

| Waiting Zone Speed Controller | yes |

| Base Chamber Speed Controller | n/a |

| Speed Controller Knob Resolution | 0,1%/click |

| Chord | 500 mm |

| Chord-to-Spacing ratio | ≥3:1 |

| Material | aluminium |

| Surface treatment | anodized |

| Cooling channels | 6 |

| Turning vane heat transfer ratio, per meter @ 10-35m/s airflow speed | >105 (±15) W/(m*K) |

TT25 Single loop (uFly25)

UF25SL Technical Documents (full version). The full technical documentation is available upon request. Please contact us.

Document archive contents:

- Building Requirements (A)

- Equipment loads (E)

On request:

- Equipment bases tolerance requirements (H)

- Wind tunnel equipment location (T)

- Cooling System (C)

- Cable networks (P)

- Service floors and ladders (K)

- Building Markup and Inspection (M)

- Site work execution program (X)