Engineering Airflow. Worldwide.

TunnelTech designs, manufactures, and services cutting-edge wind tunnel systems for customers across the globe. With our headquarters in Stuttgart, Germany, we bring German engineering and practical efficiency into every project—supporting everything from indoor skydiving and training to automotive aerodynamics, drone validation, aerospace research, and defense applications. Subsonic, supersonic, vertical, or custom-built: we create airflow environments you can trust.

German Engineering, Global Excellence

Since 2014, TunnelTech has redefined the standards of indoor skydiving technology. Our high-performance wind tunnels are operational worldwide—from Asia and the Middle East to Europe and the Americas—supporting premier entertainment venues, strategic military training facilities, and advanced research institutions.

TunnelTech stands at the forefront of aerodynamic innovation. Delivering German engineering excellence, our portfolio ranges from Europe's largest flight chambers to record-breaking projects in Qatar, consistently expanding the operational capabilities of vertical wind tunnel technology.

Headquartered in Stuttgart, Germany, TunnelTech houses the industry's largest in-house engineering team. By integrating mechanical, electrical, and software development under one roof, we deliver fully optimized, turnkey wind tunnel ecosystems tailored to your specific operational requirements.

Choose Your Perfect Solution

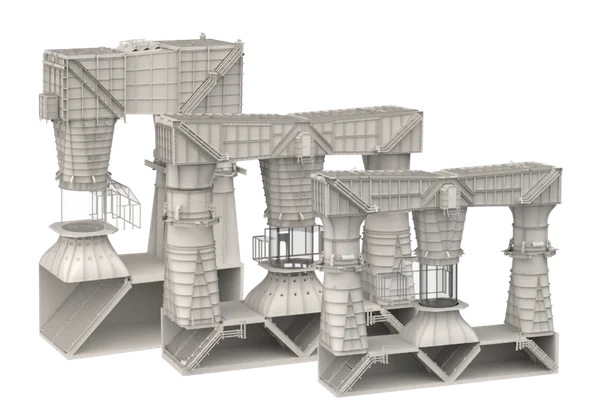

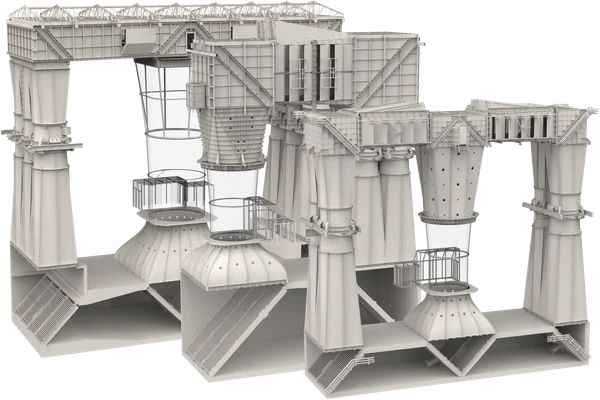

From compact µFLY models to FAI-compliant PRO Series flight chambers, we engineer scalable wind tunnel solutions designed for operational efficiency and championship-level performance.

µFLY

The definitive compact solution for retail and entertainment venues. The µFLY series delivers the authentic sensation of bodyflying in a space-efficient footprint, maximizing throughput and profitability without sacrificing the guest experience.

SMART

The global benchmark for modern indoor skydiving facilities. Fully FAI-compliant, the SMART series perfectly balances professional-grade aerodynamics for sport flyers with the operational efficiency required for a high-ROI commercial business.

PRO

The undisputed pinnacle of wind tunnel technology. Engineered for military and elite sporting applications, the PRO series features our revolutionary passive cooling system—slashing energy costs by up to 60%—while operating as the quietest facility on the global market.

Why Choose TunnelTech?

Leveraging the EVG Group's 40+ years of industrial fan manufacturing experience, we combine deep aerodynamic heritage with cutting-edge innovation to define the industry standard for reliability and efficiency.

Unbeatable Efficiency

Redefine your operational economics. Our proprietary passive cooling technology dramatically reduces power consumption, delivering up to 60% energy savings compared to conventional active cooling systems.

Zero Failures

Unrivaled mechanical longevity. With millions of cumulative operating hours across our global fleet, our precision-balanced drive trains boast a flawless track record, demonstrating absolute reliability in even the most demanding environments.

Sustainable Technology

Sustainable by design. Through superior aerodynamic efficiency and lightweight carbon-fiber construction, TunnelTech facilities significantly minimize energy waste and lower the carbon footprint of indoor skydiving operations.

Competition Ready

FAI-compliant engineering selected to host premier international indoor skydiving championships, delivering the precision airflow required by world-class athletes.

FlyStation Japan

The fastest, quietest, and most powerful 15ft wind tunnel, fully compliant with strict local safety and earthquake resistance requirements.

LuxFly Belgium

Currently the quietest and most elegant wind tunnel in the world with a free-standing glass chamber elevated by a surrounding amphitheater.

FlyStation Korea

The pioneer in commercial indoor skydiving in the country, transforming the outskirts of Seoul into a vibrant activity center.

Low-angle view from the safety net of an instructor taxi flying a student near the top of the chamber.

This low-angle view captures the flight chamber from the safety net looking upward. An instructor is performing a taxi flight with a student near the top of the chamber, close to the turning vanes and the base jumping camera. The pair is flying at a height of approximately 20 meters. The perspective highlights the vertical scale of the glass walls and the architectural framework surrounding the airflow column.

1 / 19

Ready to Build the Future?

Partner with our Stuttgart-based engineering team to define your requirements and realize your vision with precision-engineered solutions.

Contact us directly