Best for image oriented or government ventures where business is secondary to vision, opportunity and publicity.

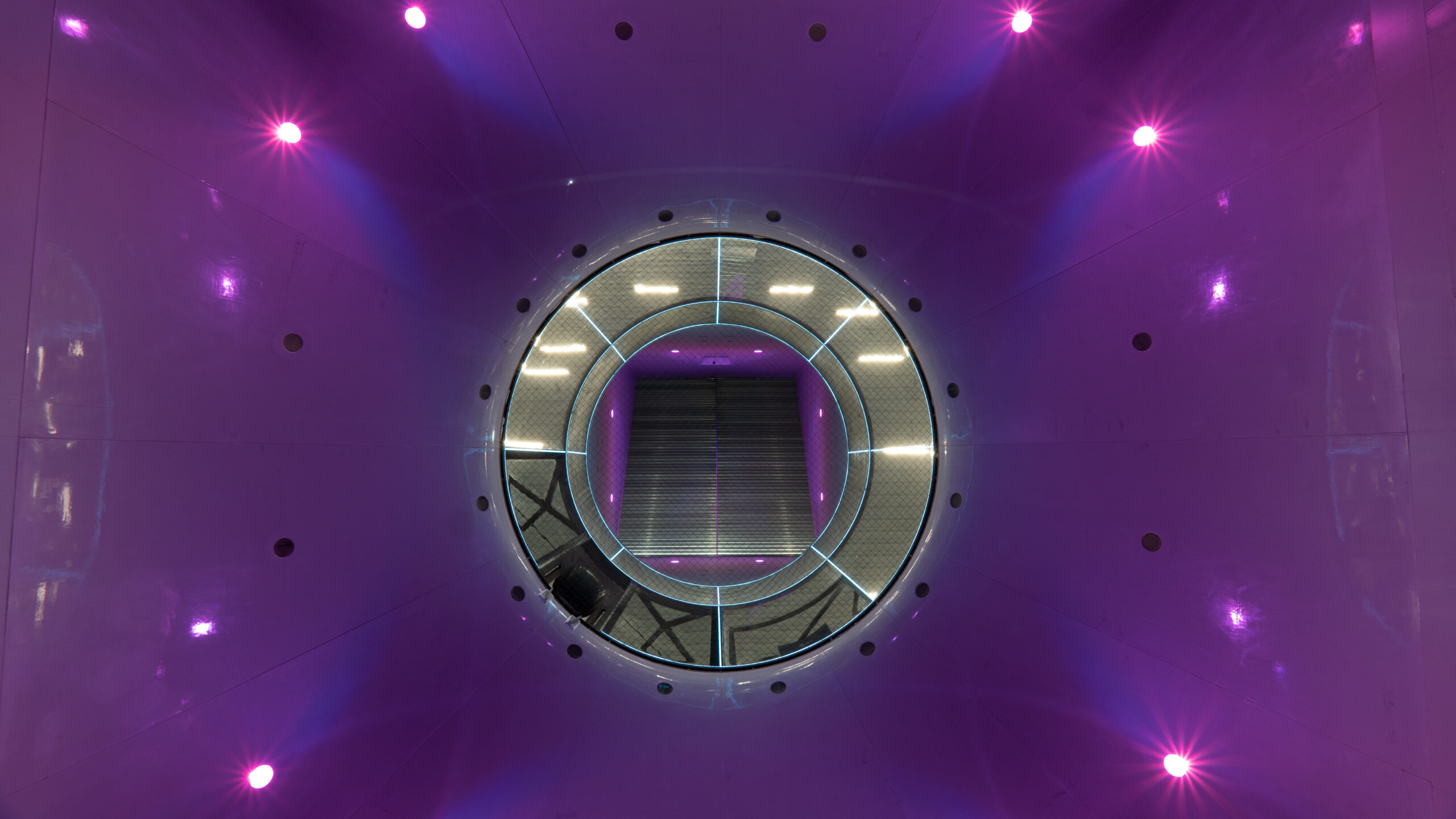

The groundbreaking indoor skydiving wind tunnel that offers an unparalleled flying experience and state-of-the-art safety features. Currently under construction in Qatar, this colossal wind tunnel boasts the second largest diameter in the world, setting new standards in the indoor skydiving industry. Its cutting-edge design and technology make it the ultimate choice for hosting world championships, including dynamic flying disciplines. Experience the future of indoor skydiving with the TT65 PRO.

The TT65 PRO’s exceptional size and innovative design make it an ideal venue for hosting the world championship, including dynamic flying disciplines. Its spacious flight chamber can accommodate larger teams and more complex maneuvers, allowing athletes to push the boundaries of their skills and showcase the true potential of indoor skydiving.

Power efficiency is crucial for indoor skydiving projects, as it directly affects operational costs, environmental impact, and long-term sustainability. The TT65 PRO’s advanced engineering ensures that energy consumption is minimized without sacrificing performance or safety. This energy-efficient design translates into lower energy bills and reduced carbon footprint, making it an attractive option for environmentally-conscious operators.

Safety is paramount in the world of indoor skydiving, and the TT65 PRO incorporates several features to ensure a secure and enjoyable flying experience for all:

1. Flight chamber diffusion ratio of 2: This design aspect guarantees a smooth and stable airflow, minimizing turbulence and enhancing the overall flying experience.

2. Well-balanced safety net with large strokes close to the walls: This feature provides a cushioned landing surface, ensuring maximum protection in case of accidental falls or collisions.

3. Curved entrance to the flight chamber: This design prevents injuries by ensuring that potential strikes go tangential to the surface, reducing the risk of direct impact.

4. Noise levels of 55 dbA in close proximity to the flight chamber: This feature reduces disturbance for bystanders and contributes to a more enjoyable environment both inside and outside the wind tunnel.

As the only TT65 PRO is still under construction, our team of experts at TunnelTech are committed to providing unmatched installation experience and support throughout the entire process. We take pride in ensuring that every aspect of the project is completed to the highest standards, from design to construction and beyond.

| Flight сhamber inner diameter | 6.5 m (21'4") |

| Glass height default | 18m (59') |

| Glass height maximum | 36 m (118'11") |

| Height | 37.7 m (123'7") |

| Length | 38.3 m (41'5") |

| Width | 14 m (45'9") |

| Height | 45 m (147'6") |

| Length | 30 m (98'4") |

| Width | 12 m (39'4") |

| Power capacity (min) | 3360 kW |

| Average time-weighted power consumption | 1171 kW |

| Power consumption @ 180 km/h | 857 kW |

| Standard power capacity | 3360 kW |

| Advanced power capacity | n/a |

| Beast power capacity | n/a |

| Noise level | 60 dBA (optional) |

| Darcy-Weissbach drag coefficient, Xi | 0.27 |

| Max. Speed @ Standard power capacity | 275 km/h |

| Max. Speed @ Advanced power capacity | 290 km/h |

| Diameter | 6.5 m (21'3") |

| Height (minimum) | 21.5 m (70'5") |

| Area | 33.16 m (108'8") |

| Default glass height | 18 m (59') |

| Glass type | chemically strengthened, non-shattering |

| Glass total thickness | ≥50 mm |

| Low iron glass | yes |

| Optional maximum glass height | up to 36 m (118'11") |

| BASE jumping chamber height | 19 m (62'3") |

| Patented safety net | maintains long stroke in close proximity to the walls |

| Safety net tensioner | 2 per cable |

| Speed drop (Diffusion rate) | 1.47 |

| Portal entrance shape | curved, collision safe |

| Portal entrance material | impact-dampening rubber |

| Entrance area speed drop | ≤1% |

| Airlock doors | automated |

| Airlock emergency exit | yes |

| Smooth decompression | yes |

| Transit time of customer groups to/from the flight chamber | <1 min |

| Supplier | Tunneltech , Germany |

| Quantity | 6 |

| Power (per fan) @ Standard power capacity | 560 kW |

| Power (per fan) @ Advanced power capacity | n/a |

| Location | return vertical airduct |

| Axel orientation | vertical |

| Diameter | 3.37 m (11') |

| Effective crossectional area | 7.68 m (25'2") |

| Blades material | carbon fibre |

| Blades count | 8 |

| Automated lubrication | yes |

| Material of FC Airjet (FC Contraction) | FRP |

| Material of FC Diffuser | glass |

| Material of return vertical airducts | FRP/steel |

| Ventilation (a.k.a. Passive Cooling) | yes |

| Max ventilation to airflow ratio | custom |

| Active Cooling System | yes (optional) |

| Additional drag, caused by active cooling system | 0 Pa (No drag) |

| Active Cooling type | through turning vanes |

| Recommended Chiller Cooling Capacity | 2400 kW (8,189,140 BRU/h)) |

| Color LED backlight strips between glass panels | yes, flicker-free (optional) |

| LED Strips power per m | 10 W |

| LED Strips frame rate | 60 fps |

| LED Projectors | yes, flicker-free (optional) |

| LED projectors default number installed (optional) | 8 - 32 (optional) |

| LED projectors max. power | 90 W |

| LED projectors max. luminous flux power | R:1950 G:2700 B:750 lumen |

| LED projector dimming capability | 0 - 100% |

| LED control from Main Panel | yes |

| LED anti-flicker function | high frequency PWM |

| LED projector PWM frequency | 1 kHz |

| LED color depth | 24 bit, 16,777,216 colors |

| LED projector color depth | 36 bit, 64 bln colors |

| Main panel control display | 28" |

| Touch screen main panel | yes |

| Flight chamber info display | 31.5" |

| Operator desk speed controller | autonomous knob |

| Waiting zone speed controller | autonomous knob |

| Base chamber speed controller | autonomous knob |

| Speed controller knob resolution | 0,1% |

| Chord | 500 mm |

| Chord-to-Spacing ratio | ≥3:1 |

| Material | aluminium |

| Surface treatment | anodized |

| Cooling channels | 6 |

| Turning vane heat transfer ratio, per meter @ 10-35m/s airflow speed | >105 (±15) W/(m*K) |