Overview

Innovation, functionality and safety are keystones of Tunneltech’s pressure doors. Designed to enhance the user experience and ensure controlled passage in professional wind tunnels and clean rooms, pressure doors are revolutionizing the way spaces are accessed and experienced.

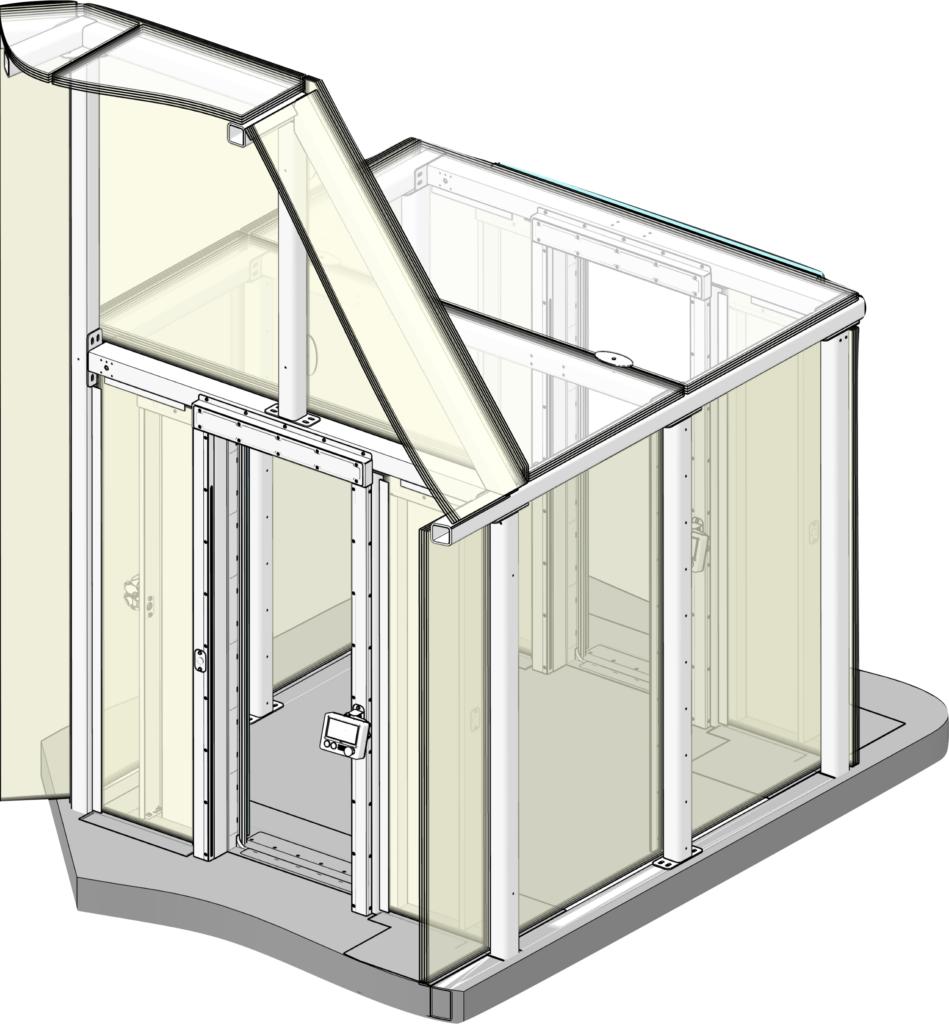

At TunnelTech, we specialize in engineering cutting-edge pressure doors that set new standards in the industry. Our doors are meticulously designed with precision and attention to detail, providing exceptional reliability and functionality. Featuring a double-leaf door system with transparent triplex glass, our pressure doors offer a clear view and ample space for easy access. The sashes, made of multiple layers of triplex glass, ensure durability and safety.

Operating our pressure doors is effortless. Athletes have full control, opening and closing the doors with touch control panels conveniently installed on both sides. The responsive electro-mechanical drive system allows for quick and efficient entry, with an opening/closing time of just 3 to 5 seconds.

Safety is our top priority. Optical safety sensors are integrated into our pressure doors to prevent accidental injuries, ensuring a secure passage in any direction. The doors also feature an inflatable pneumatic seal that guarantees a tight seal and can withstand air pressure drops of up to 4.5 kPa.

In addition to wind tunnels, our pressure doors find applications in other industries that require controlled environments. They are ideal for special clean rooms, providing airtight seals and efficient separation of room volumes.

Choosing TunnelTech’s pressure doors means gaining a competitive advantage. Our innovative inflatable seal technology ensures reliable and high-quality separation of room volumes, while the double-leaf design reduces opening/closing time for improved efficiency. With TunnelTech’s pressure doors, you can enhance safety, efficiency, and functionality in your projects.

Features and Design:

Pressure doors are meticulously designed and engineered to meet the demanding requirements of professional wind tunnels and clean rooms. These cutting-edge door systems offer a range of features that enhance functionality, efficiency, and user experience:

Hermetic Seal: Pressure doors incorporate an inflatable pneumatic seal that ensures airtight separation between different areas. This hermetic seal guarantees the invariability of air flow parameters in the flight zone, preventing air exchange and maintaining precise airflow control.

Double-Leaf Design: The pressure doors feature a double-leaf configuration with sliding leaves made of transparent triplex glass. This design allows for a wide entrance, facilitating the smooth and convenient passage of athletes and personnel.

Quick Opening/Closing: With an opening/closing time of 3 to 5 seconds, the pressure doors provide rapid access to the designated areas. This swift operation minimizes disruptions and optimizes the efficiency of workflow within the wind tunnel or clean room environment.

Electro-Mechanical Drive: The sashes of the pressure doors are driven by an electro-mechanical drive system, ensuring smooth and precise movement. This mechanism enables effortless operation and reliable performance, enhancing the overall user experience.

Optimal Safety Features: Safety is a top priority in pressure door design. These doors are equipped with optical elements that provide protection against accidental pinching of limbs during passage. The design takes into account the safety of athletes and personnel, ensuring a secure and worry-free experience.

Touch Control Panels: Each pressure door is equipped with touch control panels installed on both sides, allowing athletes to open and close the doors themselves. The intuitive interface and user-friendly controls enhance convenience and autonomy.

Durable Construction: Pressure doors are built to withstand demanding conditions and provide long-lasting performance. The multiple layers of triplex glass in the sashes ensure robustness and durability, while maintaining transparency for visibility.

User Experience and Convenience:

Self-Operated Control: The pressure doors are designed to be operated by the users themselves. With touch control panels installed on both sides of the doors, athletes have full control over the opening and closing process, allowing for independent and efficient passage.

Intuitive Interface: The touch control panels feature an intuitive interface that is easy to understand and navigate. Clear instructions and visual indicators ensure that users can operate the doors with confidence, minimizing the need for external assistance.

Swift and Effortless Passage: The pressure doors’ quick opening and closing time, coupled with the smooth movement facilitated by the electro-mechanical drive system, enable swift and effortless passage for athletes. This eliminates delays and interruptions, allowing for a seamless workflow within the wind tunnel or clean room environment.

Transparent Design: The use of transparent triplex glass in the sashes of the pressure doors provides visibility and transparency, enhancing the overall user experience. Athletes and personnel can observe the surroundings, promoting a sense of connection and enhancing safety during passage.

Safety Precautions: The pressure doors are equipped with optical elements to prevent accidental pinching of limbs during passage. These safety features are meticulously integrated into the design, ensuring the well-being and comfort of users.

Reliability and Durability: Pressure doors are engineered to deliver reliable performance and withstand the demanding conditions of wind tunnels and clean rooms. The durable construction and robust materials used in their design ensure longevity, minimizing downtime and maintenance requirements.

Applications:

Wind Tunnels: In wind tunnel facilities, pressure doors are utilized as the gateway for athletes to access the flight zone while maintaining the integrity of the airflow and pressure within the facility. They ensure a controlled environment for aerodynamic testing, research, and training activities.

Clean Rooms: Pressure doors are commonly used in clean room environments where strict control of air quality, particulate contamination, and pressure differentials is necessary. These doors provide airtight seals and prevent the transfer of contaminants, ensuring a controlled and sterile environment for sensitive manufacturing processes, scientific research, and pharmaceutical production.

Aerospace and Aviation: Pressure doors play a crucial role in aerospace and aviation industries. They enable safe entry and exit of personnel and equipment into controlled environments, such as aircraft assembly areas, engine testing facilities, and maintenance hangars. Pressure doors help maintain the required air pressure differentials and prevent contamination in these critical areas.

Research Facilities: Research institutions and laboratories utilize pressure doors to control the airflow and maintain specific environmental conditions in controlled research areas. These doors help prevent cross-contamination, ensure controlled temperature and humidity levels, and create isolated spaces for scientific experiments, testing, and analysis.