Indoor Skydiving Wind Tunnels

A comprehensive portfolio of German-engineered solutions designed to meet diverse operational needs—from high-throughput entertainment attractions to FAI-compliant sport facilities and tactical military training centers.

Select a Product Line

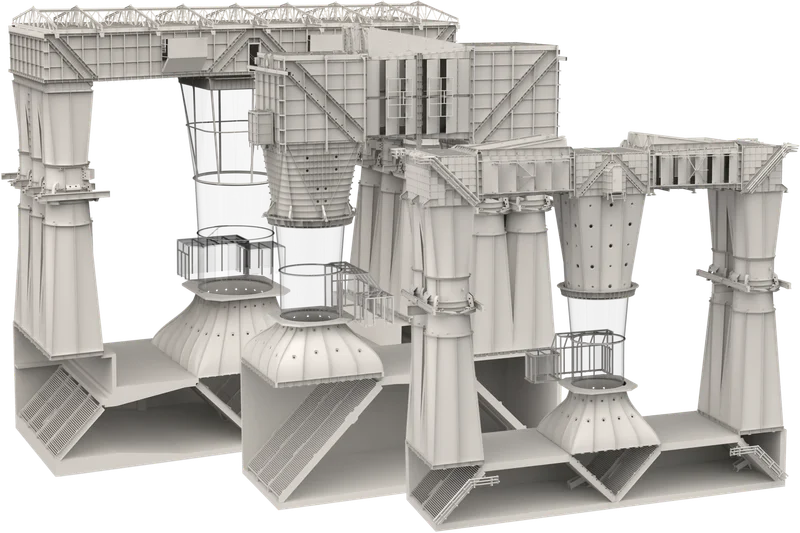

PRO Series

The pinnacle of German aerodynamic engineering. PRO series installations define the global standard for power, energy efficiency, and acoustic excellence.

Engineered with our revolutionary passive cooling technology, the PRO Series reduces power consumption by up to 60% while eliminating the need for external chillers. Operating at a whisper-quiet 51 dBA, these high-performance tunnels redefine site feasibility, allowing for installation in noise-sensitive residential areas and premium urban locations. Experience the future of sustainable aerodynamic technology.

Key Features

- Market-leading aerodynamic efficiency with a Darcy-Weißbach friction factor of just 0.185.

- Revolutionary passive cooling technology delivering up to 60% in operational energy savings.

- Ultra-quiet operation with acoustic emissions reduced to as low as 51 dBA.

- Speeds exceeding 300 km/h

- Extended glass flight chambers up to 11m high for maximum visibility and visual impact.

- Available in three high-performance configurations: TT45, TT52, and TT65 models.

Target Applications

Elite Training

World-class athlete development

Championships

International competition hosting

Military Training

Professional military applications

Research

Aerodynamics research facilities

Explore Individual Models

See Our Work

Witness German engineering in action through our diverse portfolio of global installations.

Two flyers training belly flying inside the Wind Alps TT45 PRO flight chamber.

Two flyers execute belly flying maneuvers within the TT45 PRO flight chamber at the Wind Alps facility in France. The upward perspective showcases TunnelTech's engineering: a 4.5m diameter cylindrical section made of perfectly round, noise-absorbing multilayer glass. This frameless design provides distortion-free visibility, essential for safety and high-level professional coaching.

1 / 103