Overview

The μFly Series: Versatility Meets Affordability

The μFly Series is designed to provide an appealing and cost-effective wind tunnel solution for a wide array of applications. Its innovative modular construction ensures that customers can assemble the wind tunnel themselves, reducing both the installation time and labor expenses. This design feature makes it an ideal choice for projects with spatial constraints or budget limitations.

Key competitive advantages of the μFly Series include:

1. Lower capital costs: The μFly Series is engineered to provide superior performance at a more affordable price point compared to other wind tunnel options on the market. This cost advantage enables businesses and organizations to invest in cutting-edge wind tunnel technology without straining their budgets.

2. User-friendly installation: The modular design of the μFly Series allows for straightforward assembly by the customer. With easy-to-follow instructions and minimal specialized tools required, the installation process is streamlined and efficient, saving time and reducing the need for expert assistance.

3. Adaptability to various environments: The μFly Series’ compact and flexible design makes it suitable for a wide range of applications and settings, including indoor skydiving facilities, entertainment centers, educational institutions, and temporary installations. Its adaptability ensures that it can meet the unique needs of different users and industries.

4. Portability and reusability: One of the most significant benefits of the μFly Series is its ability to be disassembled, transported, and reassembled in a new location. This feature provides users with the flexibility to relocate their wind tunnel facility as needed, making it an excellent long-term investment that can adapt to changing business requirements or market conditions.

Overview of the μFly Series: μF32 SL The μF32 SL is the flagship model of the μFly Series, offering a compact and budget-friendly solution for indoor skydiving facilities, small training centers, and entertainment venues. Key features of the μF32 SL include:

- Flight chamber diameter: 3.2 meters

- Compact volumetric dimensions (WxLxH): 5x11x19 meters

- Modular design, allowing for easy assembly and disassembly by the customer

- Maximum wind speed: 240 km/h

- Noise level: 63 dBa in close proximity to the flight chamber

- Designed for maximum capital cost savings

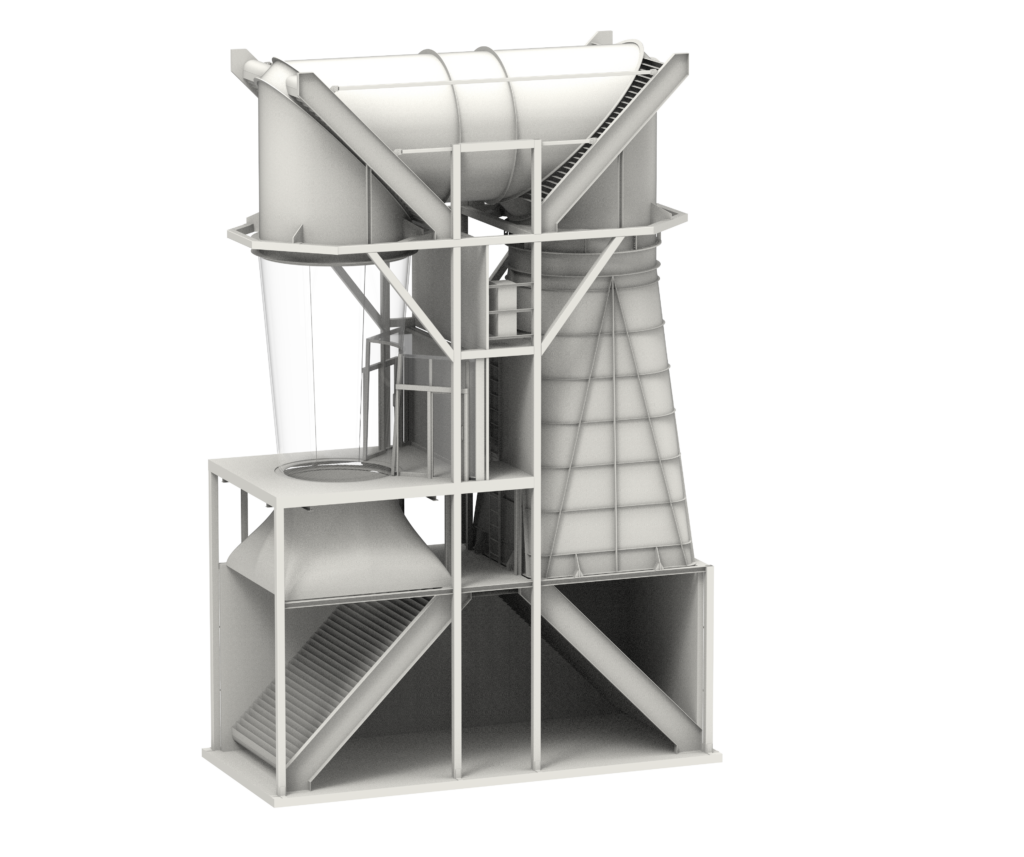

The μF32 SL features advanced aerodynamic engineering, such as turning vanes and optimized diffusion ratios, ensuring a smooth and enjoyable flight experience. The turning vanes are designed to facilitate the airflow through the corners with minimal friction, while the diffusion ratio ensures a safe and stable environment for flyers. The cylindrical flight chamber provides increased safety, reducing the likelihood of a flyer colliding with the wall during flight.

Where the μFly Series Can Be Used

The μFly Series μF32 SL is a versatile and adaptable wind tunnel solution that caters to various applications and industries. Here are some more detailed examples of where the μFly Series can be utilized:

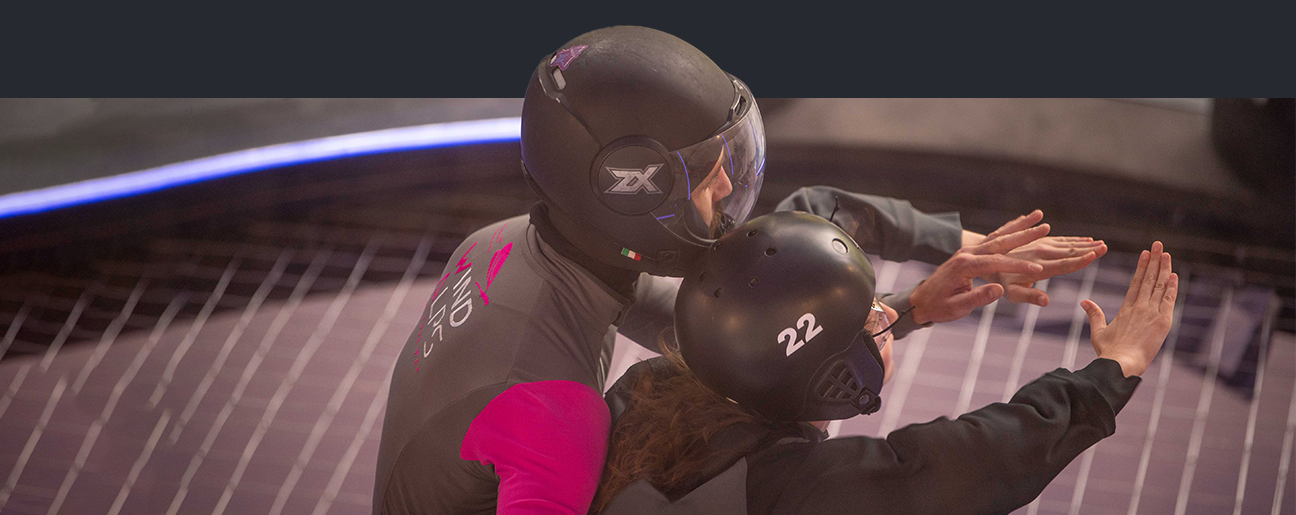

Smaller indoor skydiving facilities or training centers: With its compact design and high-quality performance, the μF32 SL is perfect for smaller indoor skydiving facilities, providing an engaging and safe environment for both novice and experienced flyers. Training centers can use the μF32 SL for teaching skydiving techniques, enhancing the skills of professional skydivers, and preparing military personnel for parachuting missions.

Entertainment centers or amusement parks: The μF32 SL is an ideal addition to entertainment centers or amusement parks looking to diversify their attractions. With its relatively small footprint and modular construction, it can be easily integrated into existing spaces or new construction projects. Offering indoor skydiving as an attraction is an excellent way to draw in thrill-seekers and adventure enthusiasts of all ages.

Pop-up events or temporary installations: The easy-to-assemble and disassemble nature of the μFly Series μF32 SL makes it perfect for temporary installations at events, festivals, or marketing activations. Organizers can set up a fully operational wind tunnel in a short amount of time, providing a unique and unforgettable experience for event attendees.

Businesses offering unique team-building experiences or workshops: Companies looking to provide innovative team-building activities can benefit from the μF32 SL. Indoor skydiving fosters trust, communication, and camaraderie among team members, making it a great option for corporate events, workshops, or retreats.

Businesses offering unique team-building experiences or workshops: Companies looking to provide innovative team-building activities can benefit from the μF32 SL. Indoor skydiving fosters trust, communication, and camaraderie among team members, making it a great option for corporate events, workshops, or retreats.

Specification

General Parameters

| Flight сhamber inner diameter | 2.8 m (9’2″) |

| Glass height default | 7.5 m (24’6″) |

| Glass height maximum | 7.5 m (24’6″) |

Dimensions Double Loop

| Height | |

| Length | |

| Width |

Dimensions Single Loop

| Height | 19.5 m (63’4″) |

| Length | 12.9 m (42’3″) |

| Width | 6 m (19’6″) |

Power Requirements

| Power capacity (min) | 630 kW |

| Average time-weighted power consumption | |

| Power consumption @ 180 km/h | 178 kW |

| Standard power capacity | |

| Advanced power capacity | 700 kW |

| Beast power capacity |

Performance

| Noise level | 65 dBa (optional) |

| Darcy-Weissbach drag coefficient, Xi | 0.3 |

| Max. Speed @ Standard power capacity | 250 kW |

| Max. Speed @ Advanced power capacity | 275 kW |

| Max. Speed @ Beast power capacity |

Flight Chamber

| Diameter | 2.8 m (9’18”) |

| Height (minimum) | 7.5 m (24’6″) |

| Area | 6.16 sq.m. |

| Default glass height | 7.5 m (24’6″) |

| Glass type | chemically strengthened, non-shattering |

| Glass total thickness | ≥50 mm |

| Low iron glass | optional |

| Optional maximum glass height | 7.5 m (24’6″) |

| BASE jumping chamber height | |

| Patented safety net | maintains long stroke in close proximity to the walls |

| Safety net tensioner | 2 per cable |

| Speed drop (Diffusion rate) | |

| Portal entrance shape | curved, collision safe |

| Portal entrance material | impact-dampening rubber |

| Entrance area speed drop | ≤1% |

Decompression Chamber

| Airlock doors | automated |

| Airlock emergency exit | yes |

| Smooth decompression | yes |

| Transit time of customer groups to/from the flight chamber | <1 min |

Axial Fans

| Supplier | Tunneltech , Germany |

| Quantity | 1 |

| Power (per fan) @ Standard power capaccity | 630 kW |

| Power (per fan) @ Advanced power capacity | 700 kW |

| Power (per fan) @ Beast power capacity | |

| Location | return vertical airduct |

| Axel orientation | vertical |

| Diameter | 4.25 m (13’95”) |

| Effective crossectional area | 11.68 sq.m. |

| Blades material | |

| Blades count | |

| Automated lubrication |

Airducts

| Material of FC Airjet (FC Contraction) | FRP |

| Material of FC Diffuser | |

| Material of return vertical airducts |

Climate Control

| Ventilation (a.k.a. Passive Cooling) | yes |

| Max ventilation to airflow ratio | 30% |

| Active Cooling System | yes (optional) |

| Additional drag, caused by active cooling system | 0 Pa (No drag) |

| Active Cooling type | through turning vanes |

| Recommended Chiller Cooling Capacity | 400 kW (1,364,856 BTU/h) |

Illumination

| Color LED backlight strips between glass panels | yes, flicker-free (optional) |

| LED Strips power per m | 10 W |

| LED Strips frame rate | 60 fps |

| LED Projectors | yes, flicker-free (optional) |

| LED projectors default number installed (optional) | 8-32 (optional) |

| LED projectors max. power | 90 W |

| LED projectors max. luminous flux power | R:1950 G:2700 B:750 lumen |

| LED projector dimming capability | 0 – 100% |

| LED control from Main Panel | yes |

| LED anti-flicker function | high frequency PWM |

| LED projector PWM frequency | 1 kHz |

| LED color depth | 24 bit, 16,777,216 colors |

| LED projector color depth | 36 bit, 64 bln colors |

Controls

| Main panel control display | 28″ |

| Touch screen main panel | yes |

| Flight chamber info display | 31.5″ |

| Operator desk speed controller | autonomous knob |

| Waiting zone speed controller | autonomous knob |

| Base chamber speed controller | autonomous knob |

| Speed controller knob resolution | 0,1% |

Turning Vanes

| Chord | 500 mm |

| Chord-to-Spacing ratio | ≥3:1 |

| Material | aluminium |

| Surface treatment | anodized |

| Cooling channels | 6 |

| Darcy-Weissbach | |

| Turning vane heat transfer ratio, per meter @ 10-35m/s airflow speed | >105 (±15) W/(m*K) |